Efficient and Safe Lubricant Handling with the OilSafe® 55 Gallon Drum Work Station

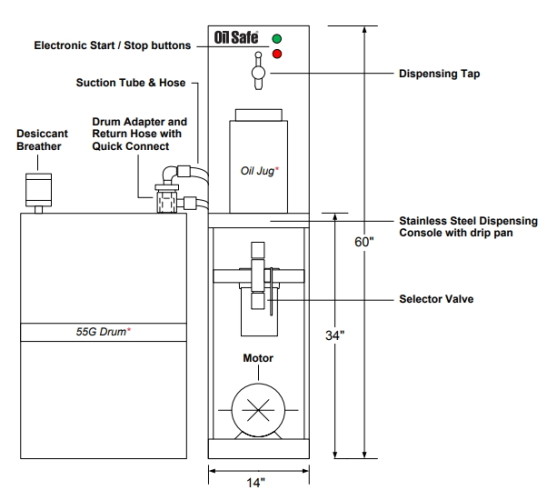

When it comes to industrial lubricant storage and dispensing, precision, safety, and contamination control are non-negotiable. The OilSafe® 55 Gallon Drum Work Station is purpose-built to meet the highest standards of fluid handling, particularly for machinery lubricants up to ISO 680. Below, we explore the features, benefits, and frequently asked questions to help you determine whether this system is right for your operations.