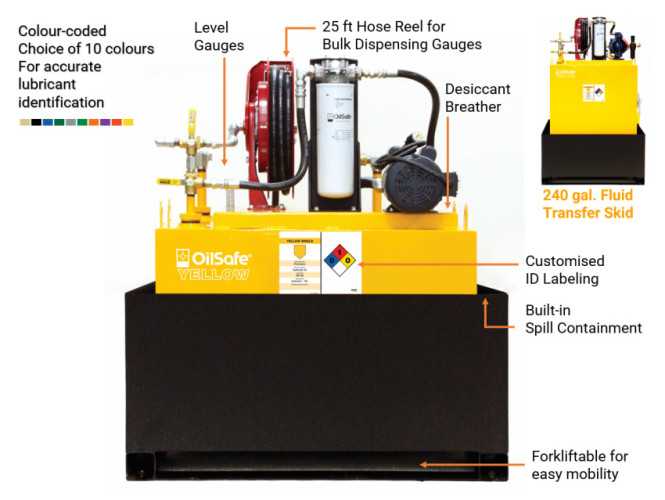

Efficient and safe Bulk Fluid Transfer with OilSafe skids

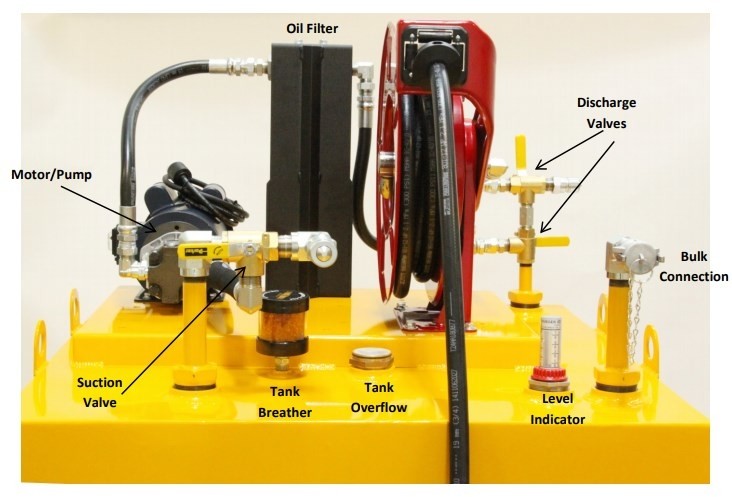

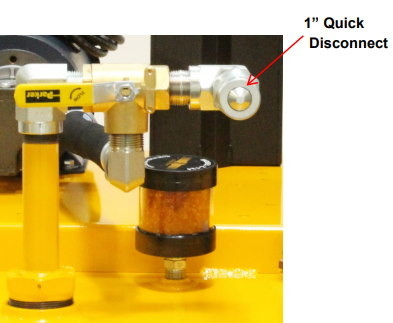

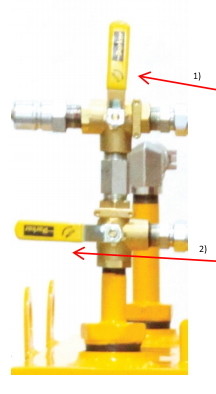

Managing industrial fluids efficiently is crucial for maintaining equipment reliability and prolonging the lifespan of lubricants. The OilSafe Bulk Fluid Transfer Skid provides a safe and effective solution for transferring, filtering, and dispensing bulk oils. Whether you need to pump oil from drums, conduct off-line filtration, or store clean fluids for later use, an OilSafe Transfer Skid can streamline your operations and improve contamination control.