Double the filters, double the performance.

The Decolube M-TWIN is a high-performance mobile oil filtration and transfer unit designed to clean lubrication and hydraulic oils with maximum efficiency. With its dual-stage filtration system, this unit removes both coarse and fine contaminants in a single pass—making it ideal for achieving strict ISO cleanliness codes with minimal effort.

Whether you're filtering new oil before use, performing routine maintenance, or flushing contaminated systems, the M-TWIN is your go-to solution for quick, reliable filtration.

What makes the M-TWIN different?

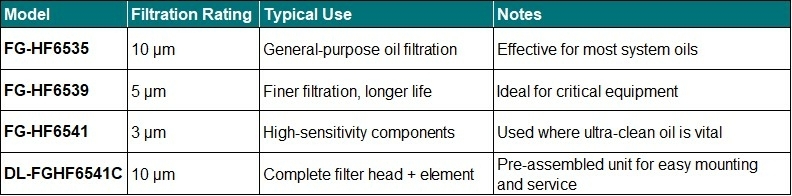

Unlike single-filter systems, the Decolube M-TWIN features two separate filters—typically a 25 µm pre-filter followed by a 5 µm micro-glass element. This two-stage setup allows progressive contamination removal, extending the life of your oil and your equipment.

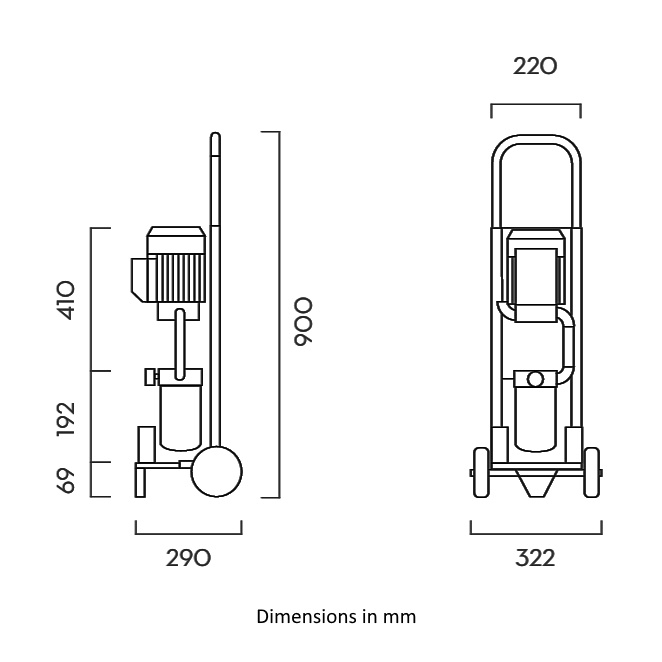

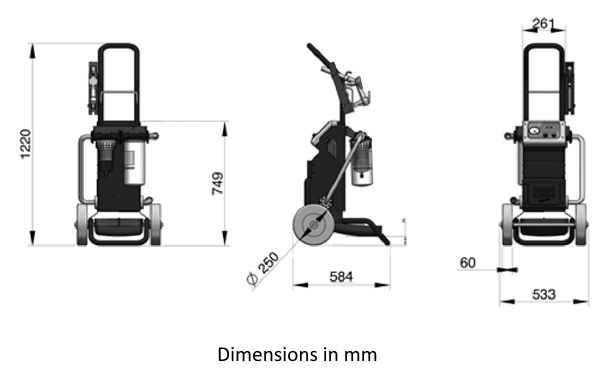

Mounted on a robust steel trolley and equipped with quick-connect hoses, the M-TWIN is designed for mobility, ease of use, and long-lasting reliability in industrial environments.

Key features

- Twin-filter design for dual-stage oil cleaning

- Self-priming gear pump ensures smooth oil transfer

- Integrated bypass valve prevents overpressure damage

- Fitted with a non-return valve for system protection

- Mounted on a strong wheeled trolley with 3-metre hoses

- Integrated suction and delivery filters

- Quiet operation and easy maintenance

Typical use cases

- Pre-filtering new lubricating oils to ISO 4406 standards

- Cleaning and transferring hydraulic oils in plant maintenance

- Flushing oil circuits in rotating machinery and hydraulic systems

- Supporting Lubrication Reliability™ programs

- Portable use across workshops, service bays and field sites

Performance data Specification

- Value Flow rate: Up to 25 l/min

- Filtration levels: 25 µm + 5 µm (standard setup)

- Power supply: 230V – 50Hz

- Max working pressure: 5 bar

- Suction hose: 3 metres, 1” diameter

- Delivery hose: 3 metres, ¾” diameter

- Noise level: < 70 dB