Moisture and airborne contaminants can cause wear, fluid breakdown, and costly downtime. Desiccant breathers and adapters protect your machinery by keeping air clean and dry as it enters lubrication systems, hydraulic reservoirs, and gearboxes. Compact, efficient, and easy to monitor; they’re essential for reliable performance across industrial applications.

Air Sentry Desiccant Breathers Line-up

Adapter Kits: Essential for Peak Performance

Essential for Peak Performance

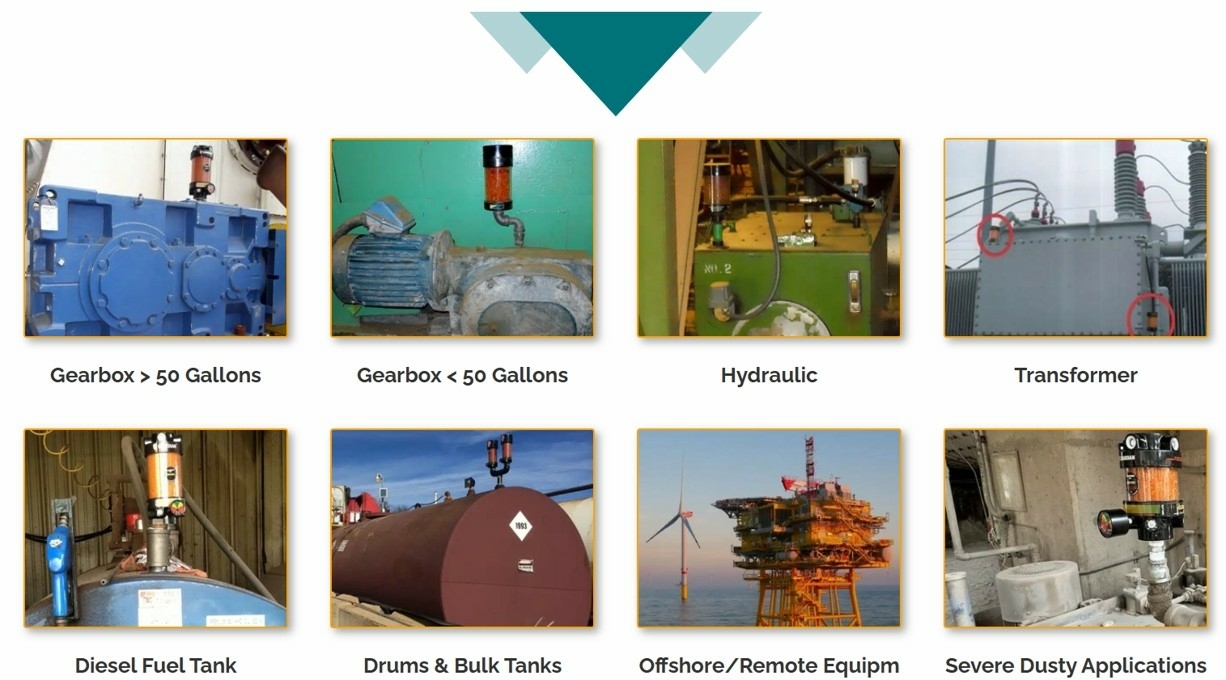

Maximise filtration efficiency with the right adapter kit. Our kits ensure a secure connection between desiccant breathers and key equipment, including:

- Drums – Keep stored fluids clean by blocking airborne contaminants.

- Gearboxes – Reduce wear by allowing only clean, dry air to enter.

- Hydraulic Reservoirs – Maintain fluid integrity and minimise moisture ingress.

Boost fluid management, extend equipment life, and support reliable operation with our versatile adapter kits.

Lubesec Desiccant Breathers

LUBESEC breathers protect lubricants in machines, storage tanks, and oil drums by filtering breather air and removing moisture and particles. They feature a 0.5-micron filter, refillable silica gel beads with a gold-to-green saturation indicator, and are available in 300g, 600g, and 1200g sizes with a ¾" BSP female connection. Safe, budget-friendly, and essential for effective lubrication cleanliness control, with various mounting adapters available.

Why Desiccant Breathers matter

Industrial machinery breathes—and that breath can invite trouble. As systems heat and cool, they draw in air. Traditional vent caps let in moisture, dust, and microscopic particles that degrade lubricants and damage internal components.

Desiccant breathers stop contamination before it starts.

Through a three-stage process, they:

- Filter out airborne debris,

- Absorb moisture with silica gel,

- And ensure only clean, dry air enters your system.

The result?

Reduced wear, fewer breakdowns, and longer equipment life. A small change that makes a big difference in performance and reliability.

How to select the right breather for my application?

Maybe you wonder "How do I select the right breather for my application". As generally known, many roads lead to Rome, or in this case lead to the Breathers you need. Take the road which fits you best.

You could pick up the phone and dial +3233122473 or send an email to info@lubretec.com, but recently we developed the Breather Selector Tool.

The Breather Selector Tool makes it easier for you to find the ideal desiccant breather for your specific application. Our detailed guide covers a variety of key criteria, helping you make well-informed choices that suit your individual requirements.

How Breathers work

How Do Desiccant Breathers Work?

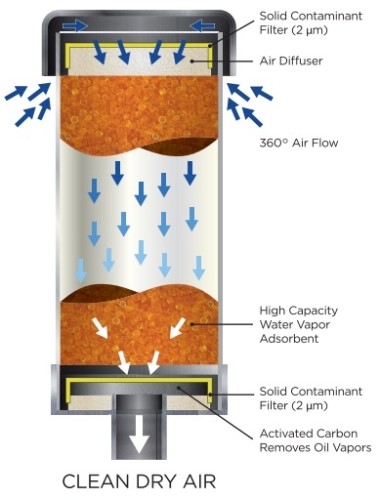

Desiccant breathers serve as the first line of defence against contamination in fluid storage tanks, hydraulic reservoirs, and gearboxes. Unlike conventional vent caps, which offer little to no protection, these breathers utilise an advanced multi-stage filtration system to ensure only clean, dry air enters your equipment.

The Three-Stage Filtration Process

Air Intake Through a 360° Opening.

External air enters the breather through a specially designed 360-degree opening. The overhanging cap shields the unit from environmental factors such as rain, snow, and wash-down processes.

Solid Particle Filtration

As air moves into the breather, it first passes through a self-cleaning filter that removes solid contaminants larger than 2 microns, preventing abrasive particles from entering your system.

Moisture Absorption with Silica Gel

The filtered air then travels through a silica gel chamber that absorbs up to 95% of airborne moisture, effectively reducing the risk of water contamination in lubricants and hydraulic fluids.

Final Filtration Before Entering the Reservoir

Before reaching the machinery, the air undergoes a final filtration stage to capture any remaining particles, ensuring that only clean, dry air enters the system.

Visual Saturation Indicator

The silica gel inside the breather serves as a real-time indicator of moisture absorption. Initially golden in colour, it gradually turns dark green as it reaches full saturation. Once fully saturated (having absorbed approximately 40% of its original weight in moisture), the breather should be replaced to maintain optimal performance.

Expelled Air and Reverse Filtration

When equipment expels air, the desiccant breather plays another critical role:

Moisture-laden air passes back through the silica gel, where excess vapour is absorbed.

If excessive internal moisture is present, the silica gel will first change colour at the bottom of the breather, indicating the presence of trapped humidity inside the system.

Oil Mist Protection

Many Air Sentry® models include an oil mist absorption layer made of carbon-impregnated foam. This additional safeguard helps trap small amounts of oil vapour expelled from the reservoir, preventing premature saturation of the silica gel. In cases where excessive oil mist is present, specialised adapters are available to enhance filtration efficiency.

By integrating desiccant breathers into your maintenance strategy, you ensure that your equipment operates under optimal conditions, extending the life of lubricants and minimising costly downtime.

Diagram 1

A tailor-made breather solution in every industry

Automotive

- Guardian-Series

- X-Series

- R-Series

- XR-Series

- Splash Sentry Adapters

Fuel Storage

- Guardian-Series

- Compound Indicating Gauge

- High-Capacity Air Filter

- Modular Stackable Ring™

- Shield Wash-Down Cap

- D-Series

Gearboxes

- Guardian-Series

- Compound Indicating Gauge

- High-Capacity Air Filter

- Modular Stackable Ring™

- Shield Wash-Down Cap

- D-Series

- L-Series

- M-Series

- R-Series

- XR-Series

- X-Series

- Z-Series

Hydraulic Reservoirs

- Guardian-Series

- Compound Indicating Gauge

- High-Capacity Air Filter

- Modular Stackable Ring™

- Shield Wash-Down Cap

- D-Series

- M-Series

- R-Series

- X-Series

- Z-Series

Air Sentry Breathers

Specifications include: Model, Check Valve PSI In/Out, Height, Diameter, Mounting Connection, Silica Gel, Maximum Adsorption Capacity / Air Flow, Maximum Reservoir Fluid Flow, Type of Medium, Isolation Check Valve, Compound Indicating Gauge, Uses Replacement Cartridge

Frequently Asked Questions

FAQ - Breathers

Which factors determine life of desiccant breathers?

The life of a desiccant breather is determined by the following four factors:

1. the number and volume of air cycles flowing in and out through the breather

2. the humidity in the environment

3. the amount of silica gel; a large one lasts longer than a small one

4. the possibility of contaminants coming out of the gear box or hydraulic system (often ignored or overlooked), encoding the silica gel and making it ineffective.

How long does a breather last?

Depending on the following 3 variables, a breather, if properly sized, lasts anywhere from 3 to 6 months:

• How humid the work environment is.

• Intake frequency and volume of breathing.

• How much silica gel is in the breather (relates to the amount of water the breather can hold).

Humid work environments tend to shorten the lifespan of a desiccant breather. This is because as the humidity increases, the silica gel reaches its maximum moisture-holding capacity faster. Once this capacity is reached, no more moisture can be removed from incoming air.

What are desiccant breathers?

To start at the beginning: according to the Cambridge Library desiccant means: "a substance used to remove moisture from something". Thus: a desiccant breather removes humidity out of the air as it is passing through a filter. The goal is to dry the air before it enters your precious reservoir.

Can't I use a vent cap instead of a desiccant breather?

A vent cap is simpler, easier to place and a cheaper solution, but.......

Equiment OEMs include breather caps on the fill port to allow expanded air to escape. However, there is one problem: while the vent caps let air out, they don't prevent small, dirty particles and moisture from entering the equipment. And there the problems start:

• A vent cap only keeps the bugs out and only filters down to about 50 micron.

• Moisture will condense inside your reservoir and water is entering your lubricants.

• Water can accelerate the oil's aging rate tenfold, resulting in sludge, varnish.....

• Dirt particles can damage bearings, valves and gears by wearing away the critical surfaces.

When should the Guardian High Pressure desiccant breather be used?

For applications where fine particle filtration is critical, Air Sentry offers a High Capacity Air Filter. The GHCAF filters particulate down to less than 1/3 of a micron, for true HEPA filtration. The pleated filter element holds substantial quantities of particulate for use in high dust environments, and the 0.3 micron filtration eliminates even bacteria size particles.

This versatile addition to the GUARDIAN line up can be used as a stand-alone particle filter, or can be used in conjunction with a standard desiccant GUARDIAN for the ultimate in particle and moisture elimination.

Suitable for the most extreme conditions.

It’s an extra protective barrier between your Guardian unit and excessively dusty environments.

What are the benefits when using desiccant breathers?

Some of the customer benefits are:

• eliminating contamination

• preventing rust and corrosion

• increased oil and filter life

• reduction of machine downtime

• reduced abrasive wear

• improved lubricant performance

• removal water contamination of reservoir

Explore the full range and check current prices online.

Explore the full range and check current prices online.