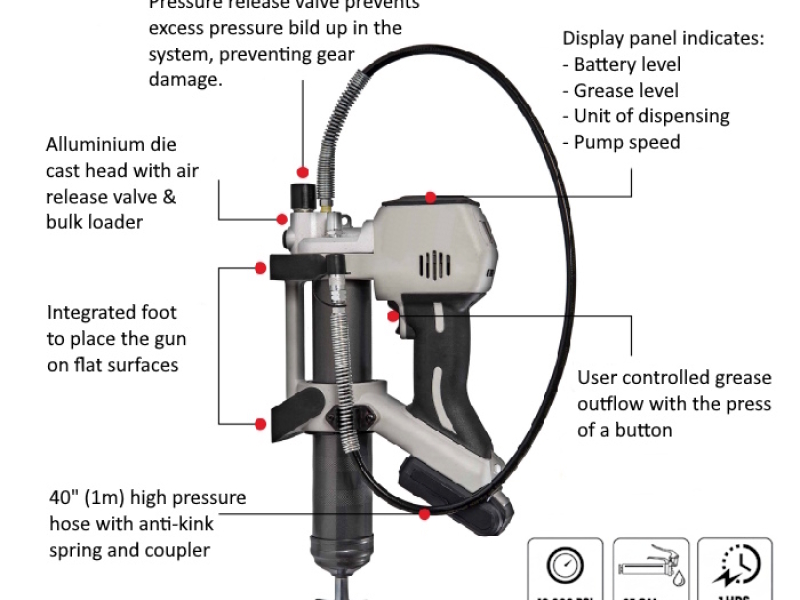

The right Grease Equipment for every lubrication challenge

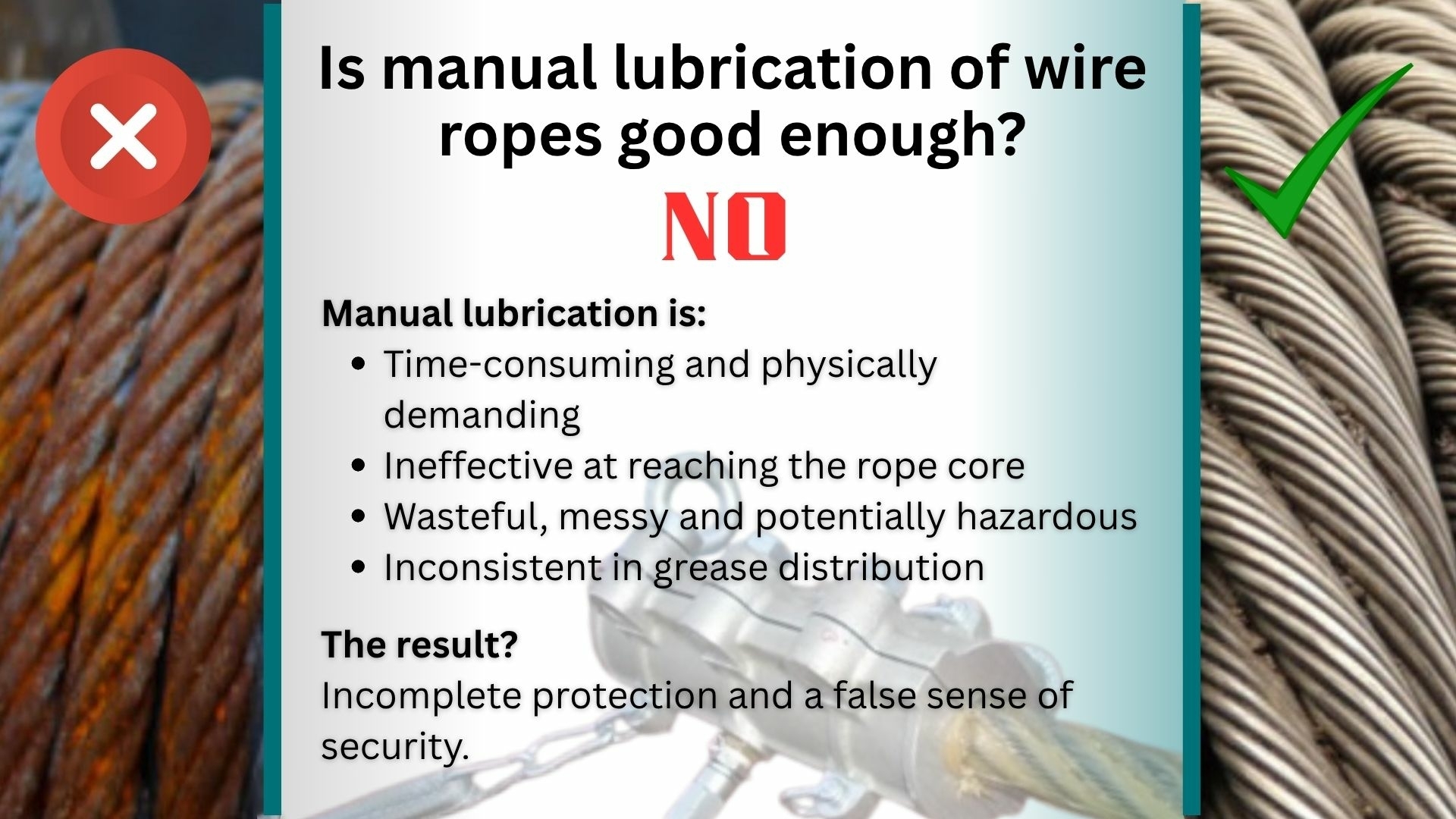

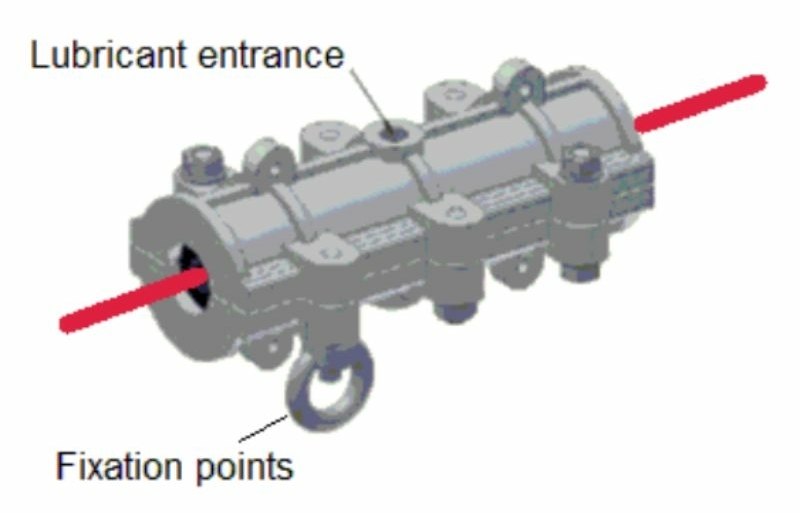

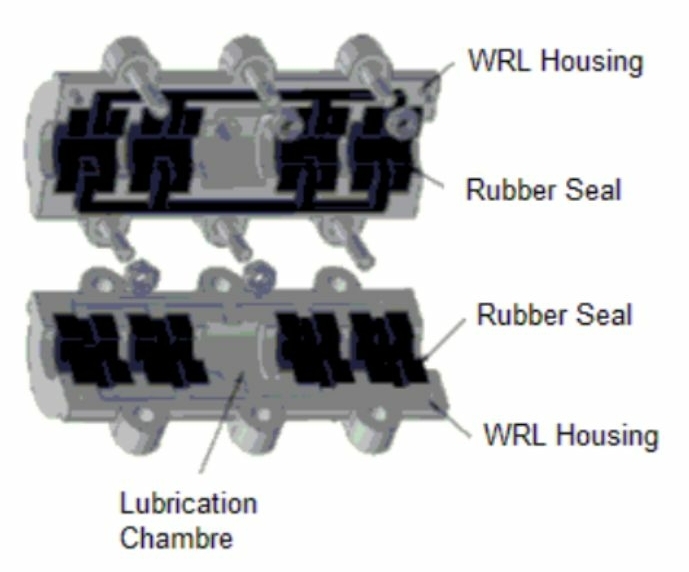

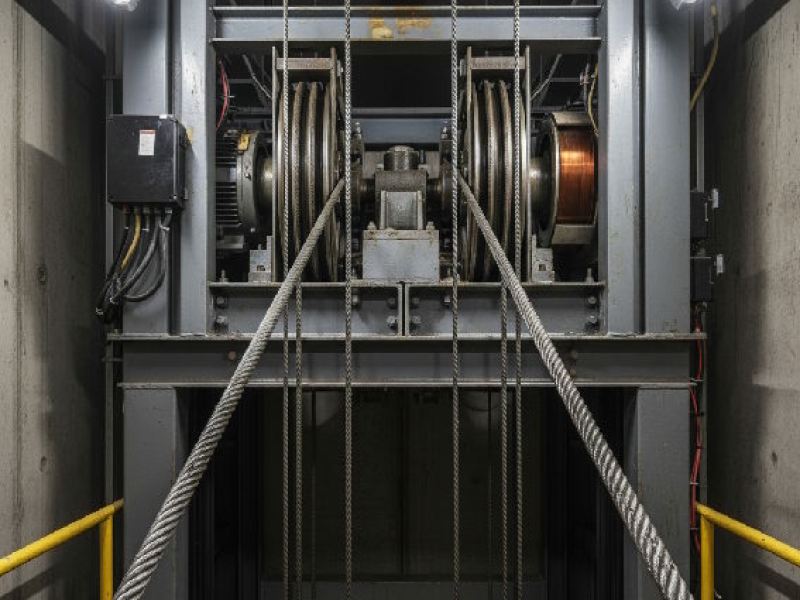

At Lubretec, we offer a comprehensive range of professional grease equipment designed to ensure reliable, efficient, and contamination-free lubrication in demanding industrial environments. Whether you’re maintaining heavy machinery, lubricating wire ropes, or managing high-volume grease applications, our products are engineered to deliver precision, durability, and safety.

From manual and pneumatic grease guns to advanced grease meters and custom wire rope lubrication systems, we help your operation stay running smoothly with the right tools for the job.