The hidden risk of using a wrong Funnel

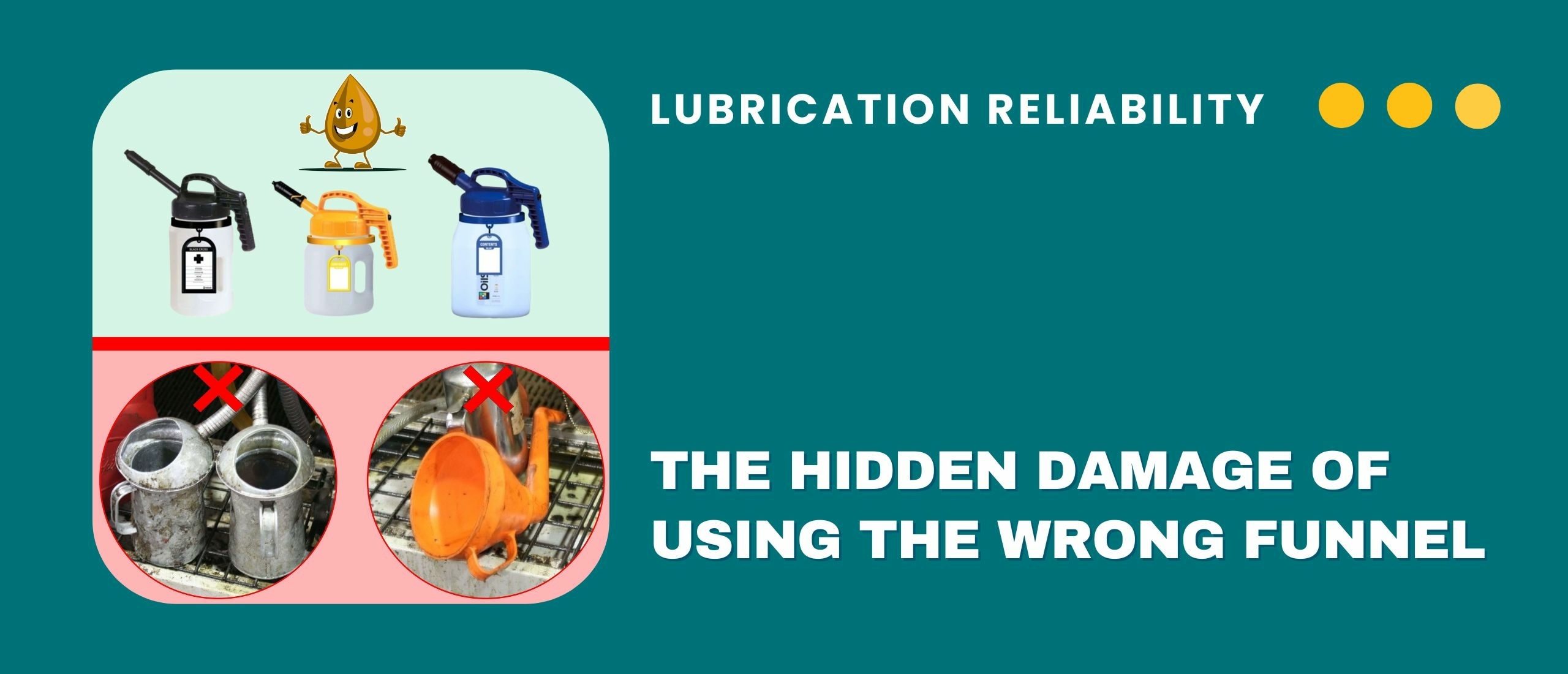

Why funnels and steel dispensing cans could be undermining your machinery

In most workshops, oil top-ups are treated as routine tasks. A funnel is grabbed, oil is poured, and the job moves on.

But few realise that this simple habit can quietly compromise lubricant performance and accelerate machine wear.

Choosing the right oil is only half the equation. How that oil is handled before it reaches the machine is just as critical.

Galvanised Funnels and Steel Dispensing Cans: A Chemical Risk

Modern lubricants are complex formulations. Beyond base oil, they contain additive packages such as:

- Anti-wear (AW) additives

- Extreme pressure (EP) additives

- One of the most common additives is ZDDP (Zinc DialkylDithiophosphate).

Here’s the problem: galvanised funnels and many steel dispensing cans contain zinc or reactive metal surfaces.

When oil additives come into contact with these metals, chemical reactions can occur. These reactions may:

- Create metallic soaps or waxy residues that block filters

- Cause additives to separate from the oil

- Reduce lubricant performance before it even enters the system

In practical terms, you may be paying for premium oil - then unknowingly stripping away the protection you purchased.

Steel dispensing cans introduce a similar risk. Even when not galvanised, prolonged oil contact with bare steel surfaces can promote additive depletion and contamination, particularly when oils are stored in them for extended periods.

The Abrasive Wear Problem

Over time, zinc coatings inside galvanised funnels degrade. Microscopic metal particles are released and carried into the lubrication system.

These particles behave like abrasive powder inside bearings and gears, accelerating internal wear and shortening component life.

This damage happens silently, often long before symptoms appear.

“Fine - I’ll use Plastic funnels instead”

Plastic sounds safer, right?

Only partly.

Plastic funnels remove the metal reaction issue, but introduce another serious problem: cross contamination. Using the same funnel for different oils allows small residues to mix. This can lead to:

- Sludge formation

- Blocked oil passages

- Chemical incompatibility between additive packages

- Breakdown of the protective oil film

Different lubricants are engineered differently. When incompatible additives meet, they can neutralise each other, leaving the machine effectively running on degraded oil.

Even when funnels are colour coded, those left exposed collect dust and moisture — which ends up inside your equipment during the next top-up.

Best Practice: Dispensing Cans

The most reliable solution for manual oil handling is the use of cans with spout lids:

✔ One container per oil type

✔ Clearly labelled and colour coded

✔ Closed to the environment

✔ No funnels required

These containers prevent cross contamination and protect oil from airborne dirt and humidity. This single change can significantly improve lubrication cleanliness and reliability.

Learn more about Dispensing kits

If Funnels must be used

When sealed containers aren’t available, strict discipline is essential:

- Apply rigid colour coding for each oil type

- Wipe funnels immediately after use with lint-free cloths

- Store each funnel in a sealed bag in a dedicated location

- Never use funnels that are dusty, wet, or visibly contaminated

Clean tools must always be ready for use, otherwise shortcuts will be taken.

The industry lesson

Lubrication excellence doesn’t begin inside the machine.

It begins with handling practices.

Galvanised funnels and steel dispensing cans can degrade additives. Shared funnels cause contamination. Exposed tools introduce dirt and moisture. Each small mistake compounds into reduced oil life, increased wear, and higher maintenance costs.

Reliability is built through attention to detail.

Because in machinery lubrication, how you add oil matters just as much as which oil you choose.

“The wrong funnel can undo everything your lubricant was designed to protect.”