Why is proper identification critical in lubrication?

Incorrect lubrication is one of the most common, and costly!, errors in machinery maintenance. When lubrication points are not clearly identified, the risk of cross-contamination increases significantly. The wrong oil or grease can lead to rapid degradation, component failure, or even complete machine breakdown.

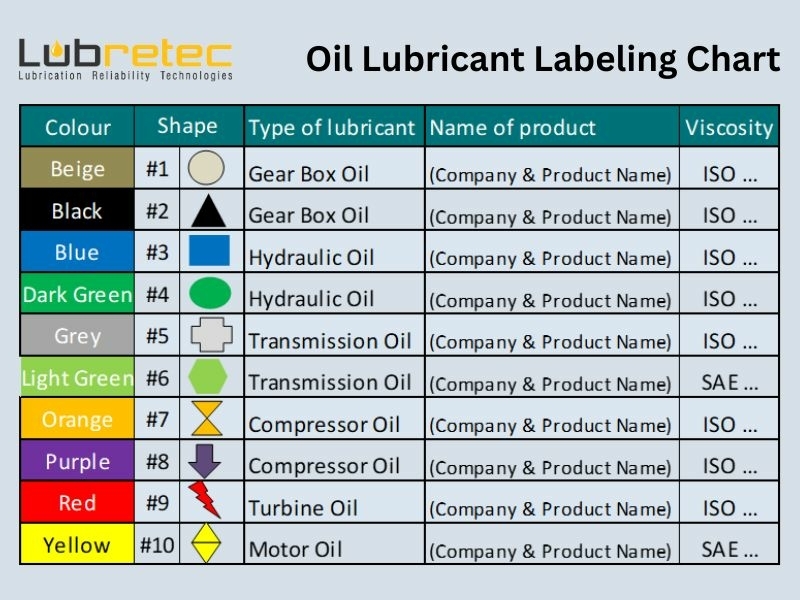

Surprisingly, it takes very little to avoid these high-impact mistakes. Through colour coding, clear labelling, and consistent identification protocols, maintenance teams can drastically reduce lubrication-related errors. Properly identifying lubricants, application points, and storage areas builds a solid foundation for reliability.

1. Colour-coding

1. Colour-coding