1. Breather Solutions for the Automotive Industry

The Challenge: Protecting Fluids During Transit

Lubricant service trucks operate in demanding environments, often navigating rough terrains on construction sites and off-road locations. These conditions expose fluid reservoirs to high levels of vibration, airborne contaminants, and humidity. Without proper contamination control, particles and moisture can enter the tanks, compromising the quality of the fluids before they even reach the equipment.

The Solution: Air Sentry® Breathers for Automotive Applications

Choosing the right breather is crucial for protecting lubricants in mobile applications. Air Sentry® offers specialised breather solutions designed to withstand the harsh conditions of the automotive and construction industries.

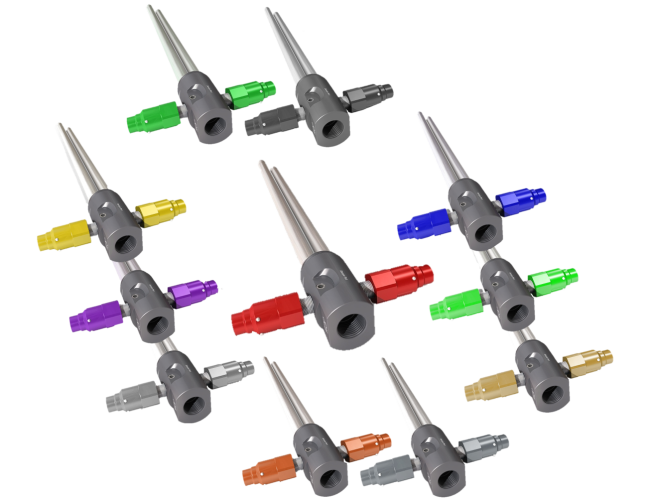

R-Series: Built for High-Vibration Environments

The R-Series breathers are specifically engineered for applications exposed to extreme vibrations. Featuring a reinforced metal base plate, these breathers provide enhanced durability, making them ideal for off-road lubricant service trucks.

XR-Series: Maximum Protection Against Moisture and Dust

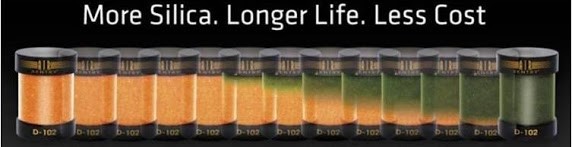

For environments with both high vibration and heavy dust or humidity exposure, the XR-Series is the best choice. It combines the robust metal base plate of the R-Series with the check valves of the X-Series, providing superior moisture and particulate control. Additionally, the XR-Series features a replaceable desiccant cartridge, offering a cost-effective and sustainable solution.

Preventing Oil Splash Contamination

In mobile applications, oil splash inside the reservoir can be a concern, as excessive oil mist can prematurely saturate the desiccant in the breather. To mitigate this issue, a remote mounting solution may be necessary.

Splash Sentry™ Adapter: Enhanced Protection Against Oil Mist

The Splash Sentry™ adapter acts as an additional safeguard, preventing oil from splashing into the breather and contaminating the silica gel. Available in 1” and 2” NPT configurations, this adapter ensures that breathers operate at peak efficiency without premature saturation.

Recommended Breather Solutions for the Automotive Industry

- X-Series – Effective contamination control in demanding environments

- R-Series – Designed for high-vibration applications

- XR-Series – Maximum protection against moisture, dust, and vibration

- Splash Sentry™ Adapter – Prevents oil mist contamination

- Guardian Series – Advanced filtration for optimal fluid cleanliness

Implementing the right desiccant breathers for automotive applications ensures that lubricants remain clean and effective, reducing maintenance costs and prolonging equipment life.