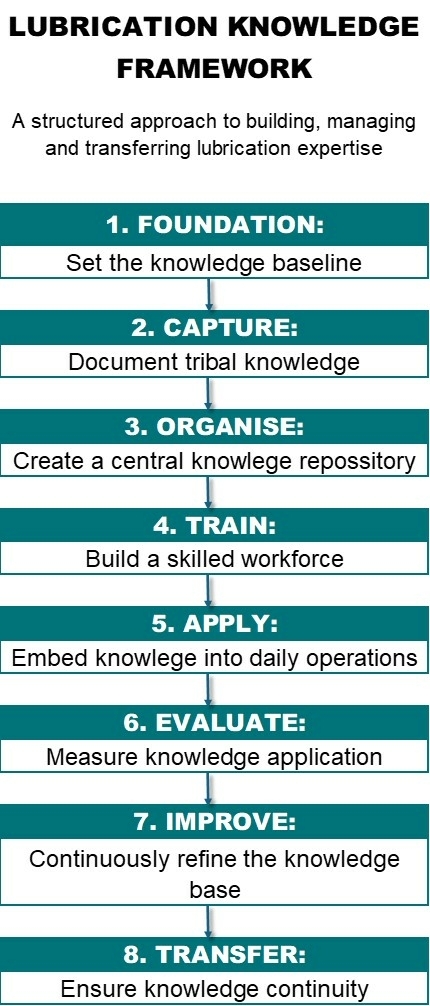

Capture, train and sustain lubrication expertise

Knowledge management closes the lubrication reliability loop: it ensures that your team retains and applies critical lubrication know-how. Without structured training, documentation, and cultural alignment, even the best lubrication systems deteriorate over time.