What is an air breather kit for spout lids? | Lubripedia

An air breather kit for spout lids is a small ventilation device that allows clean air to enter a container as lubricant is dispensed.

It prevents vacuum formation inside the container, ensuring a smooth and consistent oil flow.

Air breather kits are often used with oil drums, transfer containers, and spouted lids in lube rooms and maintenance workshops.

Function of an air breather kit:

When oil or lubricant is poured from a closed container, a vacuum can form, restricting flow and causing uneven or spluttering discharge.

An air breather kit solves this by:

- Allowing filtered air to enter as fluid is released.

- Maintaining steady internal pressure.

- Preventing dust, dirt, and moisture from entering the lubricant.

- Improving dispensing efficiency and cleanliness.

In lubrication management, clean air entry is essential to avoid introducing airborne contamination during fluid transfer.

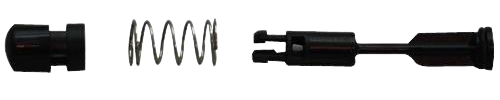

Components:

A typical air breather kit includes:

- A breather vent or filter cap – lets air flow in but blocks dust and debris.

- A fitting or adapter – connects the breather securely to the spout lid.

- Sometimes a check valve – prevents oil leakage or backflow when the container is tilted.

These components are designed to be durable, easy to clean, and resistant to oil and chemicals.

Air breather kit for OilSafe spout lids

Air breather kit for OilSafe spout lids

Applications:

- Oil and lubricant storage containers.

- Portable oil transfer and dispensing units.

- Drum-mounted pump systems.

- Maintenance and lubrication workshops.

- Industrial and field lubrication operations.

Air breather kits are particularly useful when pouring or pumping oil from sealed drums or transfer containers.

Benefits:

- Ensures smooth, controlled oil dispensing.

- Prevents air locks and splashing.

- Protects oil quality by filtering incoming air.

- Reduces the risk of contamination during handling.

- Improves ergonomics and efficiency in daily maintenance tasks.

Maintenance and best practices:

- Keep the breather clean and free from dust or oil residue.

- Replace the breather element if it becomes clogged or saturated.

- Ensure the kit is tightly fitted to avoid leaks.

- Store containers with breathers capped when not in use.

Proper use of air breather kits supports clean oil handling and contamination control across your lubrication system.