What is a HEPA filter?

HEPA EXPLAINED

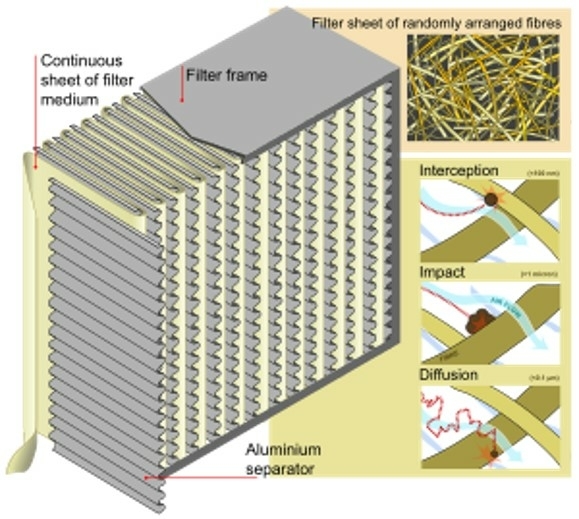

HEPA, high-efficiency particulate air filter, also known as high-efficiency particulate absorbing filter and high-efficiency particulate arrestance filter, is an efficiency standard of air filter.

HEPA filter - source: Wikipedia

Filters meeting the HEPA standard must satisfy certain levels of efficiency. Common standards require that a HEPA air filter must remove from the air that passes through at least 99.95% (ISO, European Standard) or 99.97% (ASME, U.S. DOE) of particles whose diameter is equal to 0.3 μm, with the filtration efficiency increasing for particle diameters both less than and greater than 0.3 μm.

HEPA filters capture pollen, dirt, dust, moisture, bacteria (0.2-2.0 μm), virus (0.02-0.3 μm), and submicron liquid aerosol (0.02-0.5 μm). Some microorganisms, for example, Aspergillus niger, Penicillium citrinum, Staphylococcus epidermidis, and Bacillus subtilis are captured by HEPA filters with photocatalytic oxidation (PCO). HEPA is also able to capture some viruses and bacteria which are ≤0.3 μm. HEPA is also able to capture floor dust which contains Bacteroidia, Clostridia, and Bacilli.

HEPA was commercialized in the 1950s, and the original term became a registered trademark and later a generic trademark for highly efficient filters. HEPA filters are used in applications that require contamination control

Applications of HEPA Filters:

- Industrial air purification and cleanrooms

- Lubrication and hydraulic oil filtration systems

- Laboratories, hospitals, and pharmaceutical manufacturing

- HVAC systems in offices and industrial plants

- Vacuum dehydration units for turbine and transformer oils

Why Is HEPA Important?

HEPA filters are essential in both industrial and maintenance environments to:

- Maintain oil, air, or lubricant cleanliness

- Protect machinery from wear and damage caused by contamination

- Improve workplace safety by reducing airborne particles

- Support cleanroom and laboratory standards

In lubrication systems, HEPA filters are often used in breathers, vacuum dehydration units, and offline filtration systems to remove fine contaminants from hydraulic and lubricating oils.