Lubristation™ M

Lubristation™ M

Portable drum, tank, and modular units with integrated pumps and filtration for contamination-free lubrication wherever you need it.

The Lubristation™ M is a range of mobile and fixed lubrication units designed for contamination-controlled oil transfer and dispensing. Available as drum-based systems, tank-equipped versions, or modular set-ups, these units combine pumps, filtration, and dispensing systems on robust trolleys or frames.

Whether mobile or fixed, the Lubristation™ M family delivers best-practice lubrication reliability by ensuring lubricants are conditioned to ISO cleanliness standards before reaching your equipment.

Why choose a mobile Lubristation unit?

Not all equipment is close to the central lube room. With the M-series, you can:

Bring contamination-free lubricants directly to remote machines

Maintain ISO 4406 oil cleanliness during every transfer

Reduce operator time spent transporting containers across the plant

Improve safety by eliminating makeshift transfer methods

Apply Lubrication Reliability™ anywhere in your facility

Lubristation™ M range

Lubristation M Drum

Lubristation M Modules

Storage – Lubricants are kept in sealed drums, tanks, or modular reservoirs.

Conditioning – Oils are filtered during recirculation and before dispensing to maintain ISO 4406 cleanliness.

Dispensing – Pneumatic pumps feed lubricants through flexible hoses and dispensing guns or taps for safe, controlled transfer.

Optional features – Digital meters, breather air dryers, and retention tanks enhance reliability and monitoring.

Pump type: Pneumatic

Filter: 10 µm standard (other options available)

Hose length: 4 m, ½"

Dispensing: Oil gun (optionally with digital meter)

Compatibility: 200-litre drums

Options: Breather air dryer, alternative filter ratings

(Specifications vary by model and configuration—see product data sheets for details.)

(Specifications vary by model and configuration—see product data sheets for details.)

M Tanks

Mobile or fixed units with integrated tanks

Various tank sizes available for different consumption rates

Built-in pumps and three-way filtration

Compact design for plants preferring tanks over drums

M Modules

Flexible modular systems, tailored to customer requirements

Can hold multiple drums or tanks within one mobile/fixed unit

Options for metering, OilSafe® compatibility, and advanced control

Best suited for plants handling several lubricants at once

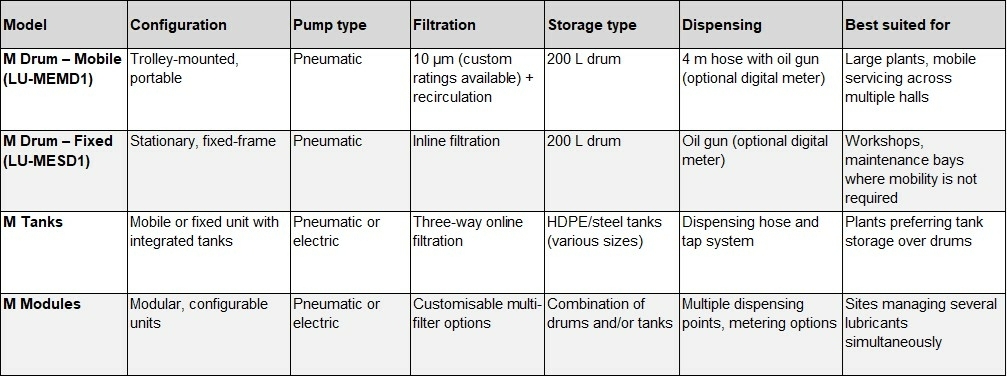

A clear comparison table for the Lubristation™ M family, showing the differences between the Mobile Drum (LU-MEMD1), Fixed Drum (MESD1), Tanks, and Modules.

Brings clean oil directly to where it is needed

Reduces contamination-related machine failures

Saves time and increases safety in lubricant handling

Portable, flexible, and built for industrial environments

Available in multiple versions to suit every plant size and setup

Contact Lubretec today to specify your Lubristation™ M solution.