In industrial and mechanical systems, wear and tear of components is inevitable. As parts degrade over time, ferrous particles (such as steel dust or iron filings) contaminate lubricants, leading to reduced equipment efficiency and eventual failure. Lubretec magnetic filters provide a proactive and highly effective way to remove these contaminants continuously—without disrupting oil flow or system pressure.

Magnetic filters

Magnetic filters

A smarter solution to ferrous contamination in lubricants

A smarter solution to ferrous contamination in lubricants

What are magnetic filters and how do they work?

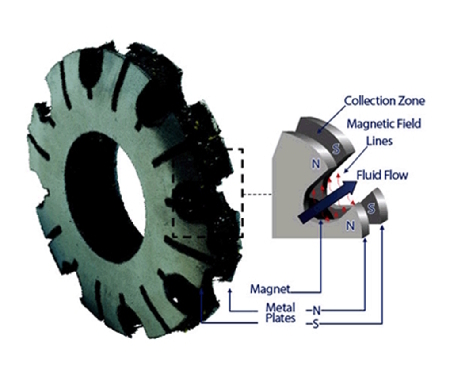

Lubretec magnetic filters offer a simple yet powerful solution: they remove ferrous (iron and steel) particles from fluids using strong magnets. These particles are a leading cause of wear, reduced performance, system failure and even product damage.

Thanks to their smart design and unique technical features, magnetic filters not only protect your equipment but also reduce maintenance costs and improve efficiency.

They are suitable for a wide range of fluids - including lubricants, coolants, water, hydraulic and transmission fluids, and cutting oils - under varying conditions of pressure, temperature, and flow.

Available in multiple models, they can be tailored to meet your specific operational needs.

Key advantages:

No restriction of flow, even when saturated with debris

Zero pressure drop across the unit

Continuous performance without the need for regular replacement

No particle release—unlike magnetic drain plugs

These characteristics make them ideal for critical systems where consistent oil cleanliness is essential.

Better than magnetic drain plugs

While magnetic drain plugs can collect metal particles at the bottom of a reservoir or sump, they are passive and limited in surface area. More importantly, particles can be dislodged during oil changes or vibration, allowing them to re-enter the lubrication circuit.

Magnetic filters, on the other hand, provide secure, high-surface-area collection and are positioned inline or in bypass, where they can continuously clean the oil as it circulates.

Seamless integration with existing systems

Designed for analysis and reliability

One of the lesser-known but powerful benefits of magnetic filters is their suitability for oil condition monitoring. The captured particles can be easily extracted and analysed under a microscope to detect failure patterns, material wear trends, and potential sources of contamination. This makes magnetic filters valuable tools for:

Root Cause Analysis (FMEA)

Predictive Maintenance

Oil condition diagnostics

When should magnetic filters be used?

Magnetic filters are particularly effective in systems where:

Ferrous wear particles are a constant by-product (e.g., gearboxes, pumps, hydraulic circuits)

Cleanliness levels are critical for performance and longevity

Oil sampling and monitoring is part of your maintenance strategy

You want to minimise filter replacements and pressure disruptions

Break the cycle of mechanical wear

Break the cycle of mechanical wear

Lubretec magnetic filters remove iron and steel particles from fluids using powerful magnets; eliminating a major cause of wear, performance loss, and system failure. With no impact on flow or pressure, they offer a clean, low-maintenance solution for a wide range of fluids, including lubricants, coolants, water, hydraulic and cutting oils.

Their smart design leads to lower maintenance costs, better equipment protection, and improved system reliability. Available in various models to suit different pressures, temperatures, and viscosities.

Ready to protect your system and reduce downtime?

Get in touch to discover the right magnetic filter for your application.