OilSafe Drums and Lids

Professional oil transfer starts with proper storage and handling

Professional oil transfer starts with proper storage and handling

Why do machines fail and what can you do about it?

Contamination is a leading cause of premature machine failure. Particulates, water, and even air can degrade lubricants and cause unnecessary wear on components. Many operations still use open containers, funnels, or repurposed bottles, exposing expensive oils to dirt and moisture. Even a small amount of debris can result in costly downtime.

The solution: a fully sealed, colour-coded oil management system

OilSafe containers and lids are designed to eliminate the guesswork and mess in lubricant storage and transfer. With sealable, reusable drums and precision-designed lids, they offer an integrated, professional approach to contamination control.

What makes OilSafe unique?

What makes OilSafe unique?

OilSafe’s system combines practical design, durable construction, and colour-coded identification, making it easier to implement lubrication best practices across any operation.

Sealable and reusable

Each drum features a wide neck and standardised threading to fit any OilSafe lid. Once sealed, they prevent ingress of dust, water and other contaminants, even when dropped or stored in less-than-ideal conditions.

Colour-coded and interchangeable

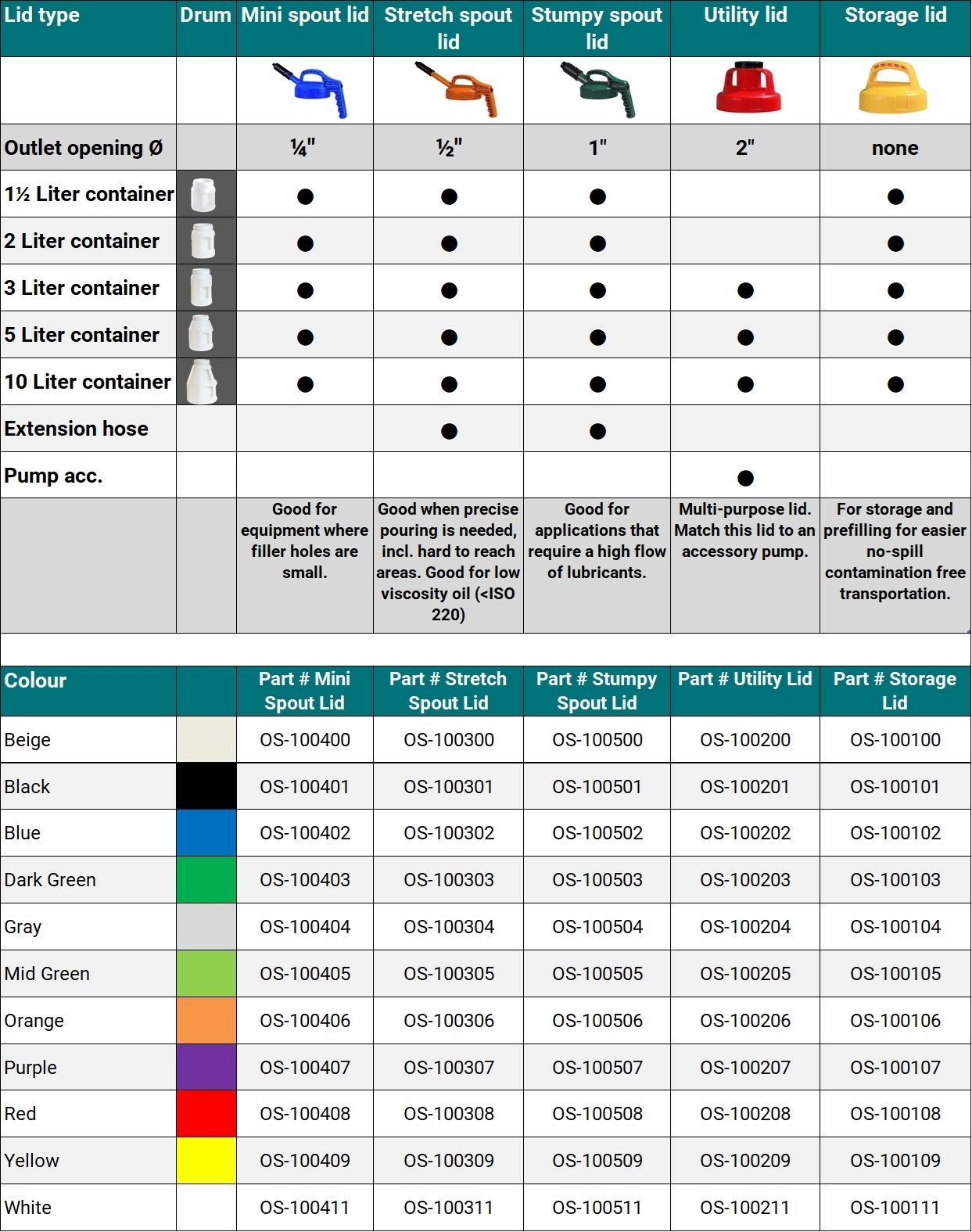

The drums are available in five sizes (1.5, 2, 3, 5, and 10 litres), and all lids fit all drum sizes. With 11 vibrant colours and 5 distinct lid styles, the system allows you to identify lubricants at a glance and avoid cross-contamination.

Which OilSafe lid is right for your application?

Choosing the right lid depends on how and where you’ll be dispensing oil. Here’s a breakdown:

Stretch Spout Lid: Best for precision pouring, particularly into narrow fill points.

Stumpy Spout Lid: Ideal for higher flow rates where speed matters.

Mini Spout Lid: Designed for the smallest fill holes, such as in small gearboxes.

Utility Lid: Versatile and fast-pouring; can also be combined with an OilSafe Pump.

Storage Lid: Perfect for long-term storage or bulk lubricant management.

Your Guide to selecting the perfect Drum and Lid for your organisation

“Can’t I just keep using my old oil drum and funnel?”

You could — but it’s risky. Traditional oil cans and open funnels expose your lubricants to the very contaminants you're trying to keep out of your equipment. With OilSafe, there’s no need for rags, makeshift labels, or guesswork.

Instead, you get a secure, intuitive system that ensures every drop of oil stays clean from storage to application.

FAQ - OilSafe drums and lids

FAQ - OilSafe drums and lids

FAQ - OilSafe drums and lids

What are the features of OilSafe containers?

The features of OilSafe containers are:

• They are available in 5 sizes:: 1,5 L. 2 L, 3 L., 5 L. and 10 L.

• Interchangeable lids and containers.

• Semi-transparent drum with graduated markings make liquid levels easy to see.

• Vent control with button in handle.

• Quick twist spout is easy to open and close. It controls flow rate and keeps dirt out.

• Ultra durable construction. Will not warp, leak, bend or break.

Is it possible to label OilSafe containers for added identification?

Yes, each container has a flat area designed for labelling. Combining this with the colour-coded lid system provides a clear and comprehensive identification method for your lubricant management programme.

Can I store OilSafe containers outdoors or in harsh environments?

While OilSafe containers are made from durable, industrial-grade plastic, it is recommended to store them in clean, dry environments away from direct sunlight and extreme temperatures to preserve lubricant quality.

Where are the containers manufactured from?

The containers are manufactured from High Density Polyethylene (HDPE) incorporating anti static agents and ultraviolet (UV) stabilizers. They withstand extreme temperatures ranging from -40°C to 80°C. The drums are not suitable for use with fuels or solvents.

How should the container be cleaned?

Recommendation on how to clean the containers to keep your oil contaminant-free::

• Begin by cleaning the container inside and outside to remove all oil.

• First clean the inside of the container. Use lukewarm, soapy water + sponge. Continue to wash the inside of the oil container until it is completely clean.

• When you are sure that the inside is clean, pour in fresh water and shake the container back and forth to rinse out all soap. Then empty it out again.

• Clean the outside of the container with a brush and soapy water. Rinse it with fresh water.

• Wipe the container dry with a lint-free rag.

• When the container is dry inside and out you can use it again.

Who benefits from using OilSafe containers?

Whether you manage a manufacturing plant, a fleet maintenance workshop, or a food pro- cessing facility, OilSafe offers advantages such as:

- Improved equipment uptime through cleaner lubrication practices

- Simplified inventory management with colour-coded identification

- Enhanced workplace safety and cleanliness

- Standardised procedures across teams and shifts

Technical specifications at a glance

- Container Sizes: 1.5L, 2L, 3L, 5L, 10L

- Threading: 3/4 lid-threading for secure fit

- Material: Industrial-grade plastic, durable and chemical-resistant

- Colours: 10 standard colours for lids

- Interchangeability: All lids fit all container sizes

How does OilSafe improve lubrication workflows?

OilSafe drums and lids support best practices in lubrication management by:

- Reducing contamination risks

- Preventing misidentification and mix-ups

- Improving speed and accuracy during refills

- Enabling safer storage and transport of lubricants

Once introduced, the system helps establish a standardised approach that technicians can follow with minimal training - reducing errors and ensuring consistent quality.