OilSafe Standard Handpump

The OilSafe standard hand pump is a robust, contamination-reducing solution for transferring lubricants safely and efficiently. It supports best practice lubrication management, protects equipment, and improves reliability across industrial environments.

OilSafe standard hand pump: a smarter approach to clean oil transfer

Poor lubrication practices remain one of the most common causes of premature equipment failure. Contamination, incorrect oil handling, and inconsistent processes quietly shorten asset life and drive up maintenance costs. This is where the OilSafe standard hand pump proves its value.

Designed for controlled, clean, and repeatable oil transfer, the OilSafe standard hand pump helps maintenance teams protect lubricants from contamination while improving efficiency and safety. In this article, we explore how it works, why it matters, and how to get the most from it in a modern lubrication programme.

Why proper oil transfer matters more than you think

Lubricating oil is not just a consumable; it is a critical machine component. Even new oil can be contaminated before it ever reaches the asset.

Common risks during oil transfer include:

- Dirt and dust entering open containers

- Moisture ingress during manual handling

- Cross-contamination between different oil types

- Inconsistent oil volumes leading to under- or over-lubrication

These issues can result in increased wear, higher operating temperatures, and reduced equipment reliability. A controlled oil transfer system is therefore essential for any operation serious about asset health.

What is the OilSafe standard hand pump?

The OilSafe standard hand pump is a manually operated pump designed specifically for use with sealed OilSafe containers and drums. Its primary purpose is to enable clean, accurate, and spill-free oil transfer from storage to application point.

Unlike improvised pumps or open pouring methods, the OilSafe pump forms part of a closed lubrication system, significantly reducing exposure to contaminants.

Key features and practical benefits

Closed system contamination control

The pump connects directly to OilSafe containers, minimising contact with airborne particles and moisture. This is particularly important in harsh industrial environments where contamination risks are high.

Durable, industrial-grade construction

Manufactured from robust materials, the pump is designed for repeated daily use. It resists chemical degradation from oils and lubricants and performs reliably over long service periods.

Controlled and consistent oil delivery

Manual pumping allows technicians to apply oil at a steady rate, reducing spills and helping maintain consistent lubrication volumes.

Simple installation and operation

No power supply or specialist tools are required. The pump can be fitted quickly, making it ideal for workshops, mobile maintenance teams, and remote locations.

Where the OilSafe standard hand pump excels

The pump is widely used across industries where equipment reliability is critical, including:

- Manufacturing and processing plants

- Mining and quarrying operations

- Power generation facilities

- Marine and offshore environments

- Food and beverage production, when paired with appropriate food-grade oils

In each of these settings, clean oil handling directly translates into reduced downtime and longer equipment life.

OilSafe Dispenser kit with standard handpump - OS-KD10206

OilSafe Dispenser kit with standard handpump - OS-KD10206

Technical performance and operating capabilities

Beyond contamination control and ease of use, the OilSafe standard hand pump stands out for its impressive mechanical performance. It is specifically engineered for high-volume, manual oil transfer in demanding industrial environments.

High-volume down-stroke discharge design

The pump uses a down-stroke discharge mechanism, allowing operators to dispense oil smoothly and efficiently with minimal effort. This design improves control during pumping and reduces operator fatigue during repetitive transfer tasks.

Optimised flow rate for daily maintenance

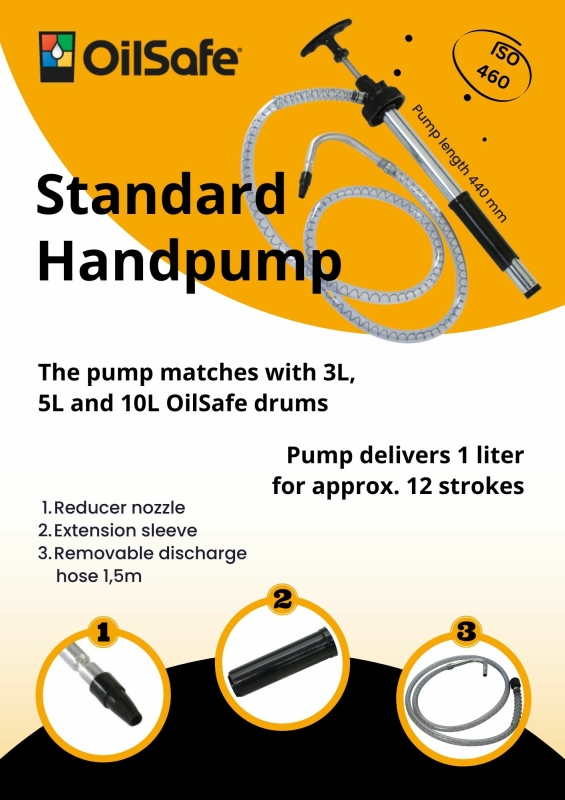

In normal operating conditions, the pump delivers approximately one litre of fluid every twelve strokes. This predictable output makes it easier for technicians to apply consistent oil volumes, supporting accurate lubrication practices and reducing the risk of overfilling.

Compatible with multiple OilSafe drum sizes

The pump is designed for seamless use with 3-, 5-, and 10-litre OilSafe drums, making it a flexible solution for workshops, maintenance carts, and mobile lubrication routes. This compatibility helps standardise oil handling processes across different applications.

Handles high-viscosity lubricants

The OilSafe standard hand pump can handle fluids up to ISO 460 viscosity under normal operating temperatures. This makes it suitable for a wide range of industrial lubricants, including gear oils and heavier circulating oils commonly used in high-load applications.

Integrated discharge hose with anti-drip control

Each pump is supplied with a five-foot removable discharge hose, complete with a hook and anti-drip nozzle. This allows for clean, targeted oil delivery while preventing residual oil from dripping after use, keeping both equipment and work areas clean.

Designed for use with the OilSafe utility lid

For optimal sealing and contamination control, the pump is intended to be used in combination with an OilSafe utility lid. This pairing ensures a secure fit, controlled dispensing, and consistent protection against airborne contaminants.

Together, these performance characteristics make the OilSafe standard hand pump a dependable, high-output solution for maintenance teams that require both efficiency and precision in their lubrication processes.

Best practice tips for using the OilSafe standard hand pump

To maximise performance and protection, consider the following best practices:

- Assign one pump per oil type to prevent cross-contamination

- Clearly label containers and pumps using colour coding or tagging

- Store containers in clean, covered areas away from dust and moisture

- Train technicians on proper pumping technique and hygiene

- Inspect seals and connections regularly for wear

These small steps significantly improve lubrication consistency and reliability.

How the OilSafe pump supports reliability-centred maintenance

Modern maintenance strategies focus on preventing failure rather than reacting to it. Clean oil transfer directly supports reliability-centred maintenance by:

- Reducing abrasive wear caused by particles

- Maintaining lubricant additive integrity

- Extending oil drain intervals

- Improving confidence in predictive maintenance data

In short, better oil handling leads to better decisions and more reliable assets.

Recommended upgrades for a complete lubrication solution

While the OilSafe standard hand pump delivers reliable and clean oil transfer on its own, its real strength becomes clear when it is combined with complementary accessories. These upgrades help create a structured, contamination-controlled lubrication system that supports consistency, safety, and long-term equipment reliability.

Colour-coded OilSafe containers

Using colour-coded containers alongside the pump makes lubricant identification fast and unambiguous. Each oil type can be assigned its own colour, reducing the risk of cross-contamination and ensuring the correct lubricant is always applied to the right asset. This approach is particularly effective in facilities managing multiple lubricant grades.

The standard pump matches with an OilSafe Utility lid

Desiccant breathers for moisture control

Moisture is one of the most damaging contaminants in lubrication systems. Desiccant breathers fitted to storage containers prevent humid air from entering while allowing pressure equalisation. This helps maintain oil cleanliness levels, especially in environments with fluctuating temperatures or high humidity.

Pump reducer nozzle for precise application

For Smaller Fill Hole Applications the pump can be upgraded with a Pump Reducer Nozzle. The pump reducer nozzle accessory fits to the aluminum anti-drip discharge pipe on the outlet end of the pump hose, and reduces the outlet diameter down to approximately 1/4".

OilSafe pump reducer nozzle (for standard and premium pumps)

OilSafe pump reducer nozzle (for standard and premium pumps)

Extension sleeve for improved reach and ergonomics

Extend Reach and Accessibility for Hard-to-Reach Fill Holes.with the extension sleeve. The extension sleeve is a valuable accessory in various industrial settings where efficient and complete fluid handling is essential. Whether it's for lubricants, oils, or other fluids, using an extension sleeve can significantly improve the pumping process and reduce the need for manual tilting or handling of the drum to access its contents. Additionally, when the extension sleeve is equipped with a reliable nitrile O-ring, it ensures a secure seal and minimizes the risk of leaks or spills during the extraction process.

By investing in a quality extension sleeve with a nitrile O-ring, businesses can optimize their fluid handling procedures, enhance productivity, and reduce wastage, all while maintaining a safe and clean working environment.

OilSafe extension sleeve for standard and premium pump

OilSafe extension sleeve for standard and premium pump

Oil analysis integration

Pairing clean oil transfer equipment with an oil analysis programme provides valuable feedback on lubrication practices. Consistent cleanliness results confirm that contamination is being controlled, while early detection of wear or degradation supports proactive maintenance decisions.

Dedicated oil transfer carts

For larger sites or high-volume lubrication tasks, mounting the hand pump on a mobile oil transfer cart increases efficiency and organisation. Carts keep containers, pumps, and accessories together, reduce manual handling, and support standardised lubrication routes.

Together, these upgrades transform the OilSafe standard hand pump from a simple transfer tool into a key component of a professional, reliability-focused lubrication strategy.

Conclusion: a small tool with a big impact

The OilSafe standard hand pump may seem like a simple piece of equipment, but its impact on lubrication quality and asset reliability is substantial. By enabling clean, controlled, and consistent oil transfer, it helps organisations reduce contamination risks, protect machinery, and lower long-term maintenance costs.

If you are looking to improve lubrication practices, reduce unplanned downtime, or build a more professional maintenance programme, investing in the right oil transfer equipment is an excellent place to start.

Want to learn more about lubrication best practices or upgrade your oil handling setup? Get in touch with a specialist or explore a complete OilSafe system to take the next step.

Explore the OilSafe Standard Handpump now!