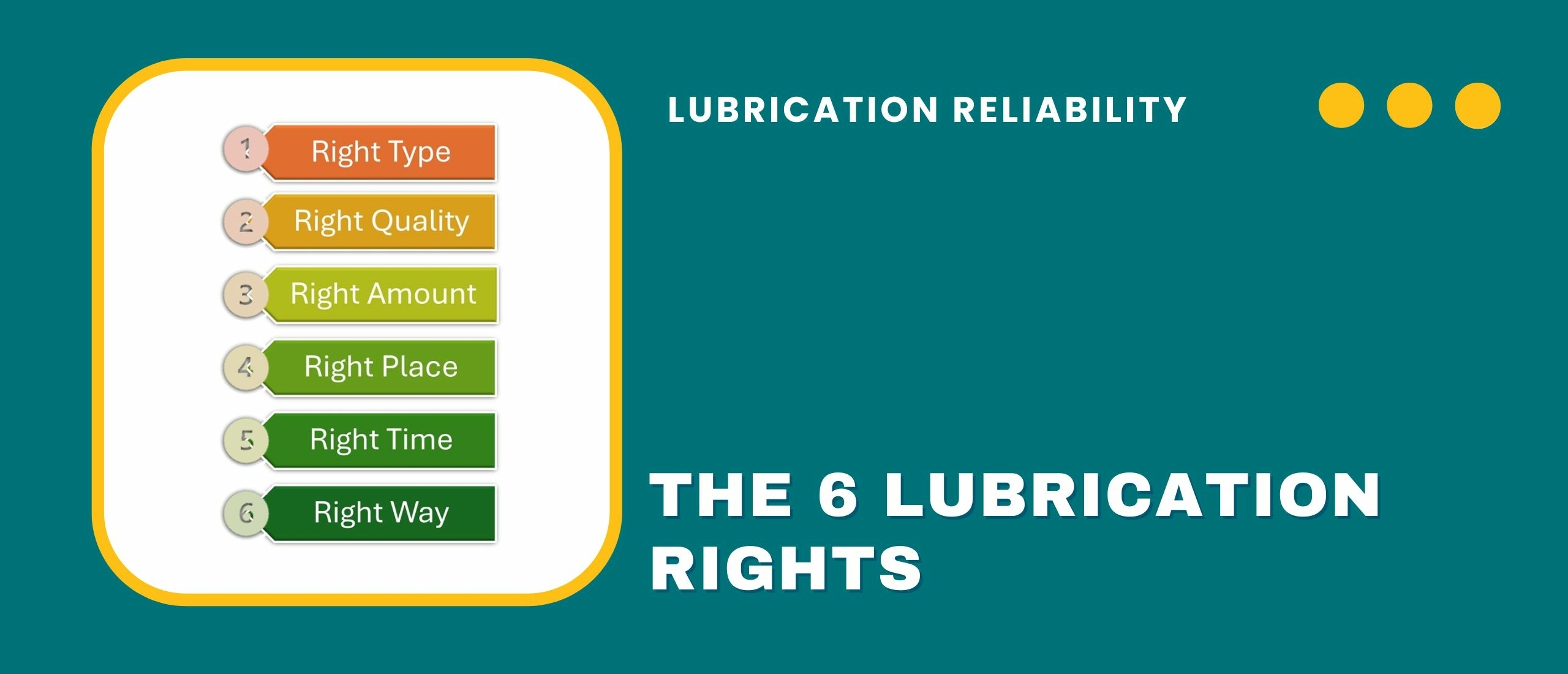

The 6 Lubrication Rights every maintenance team should follow

Poor lubrication is one of the leading causes of equipment failure. By following the 6 lubrication rights: Right lubricant, Right place, Right time, Right amount, Right method, and Right frequency, you can significantly increase the lifespan of your machinery, reduce maintenance costs, and improve reliability.

Optimal lubrication isn't just about pouring oil into the gears and hoping for the best

Optimal lubrication isn't just about pouring oil into the gears and hoping for the best

Why lubrication still fails in many industries

Despite the widespread understanding that lubrication is essential for machine health, many businesses still experience equipment failure due to poor lubrication practices. Often, it's not due to negligence, but because the process isn't standardised or consistently followed.

The solution?

Adopting a disciplined, systematic approach, known as the Six Lubrication Rights.

1. The Right lubricant

Selecting the correct lubricant is the foundation of effective lubrication. Each machine has specific requirements based on speed, load, operating temperature and environment. Using the wrong oil or grease can lead to increased wear, overheating or failure.

💡 Helpful tip:

Consult OEM specifications and consider application-specific additives, viscosity grades, and base oil types.

2. The Right place

Even the best lubricant won't help if it's applied to the wrong component. Misapplication leads to both over-lubrication and under-lubrication, which can cause significant damage.

💡 Helpful tip:

Use colour-coded systems and clear labelling to match lubricants to their correct lubrication points.

3. The Right time

Lubrication schedules should be based on operating hours, environmental conditions, and historical data—not just arbitrary dates. Delays in lubrication can result in metal-to-metal contact and irreversible damage.

💡 Helpful tip:

Use CMMS (Computerised Maintenance Management Systems) or route-based planning to stay on schedule.

4. The Right amount

More is not better when it comes to lubrication. Over-lubrication can cause heat build-up, energy loss, and seal failure. Under-lubrication causes increased friction and wear.

💡 Helpful tip:

Use calibrated dispensing tools to apply precise amounts and consider automated lubrication systems where applicable.

5. The Right method

How the lubricant is applied matters. Contamination is one of the biggest enemies of effective lubrication, and using unclean tools or incorrect techniques can introduce dirt and moisture.

💡 Helpful tip:

Train your team on proper lubrication techniques and use clean, sealed containers and tools.

6. The Right frequency

Not all machines require daily or weekly lubrication. Some may need attention after every production cycle, while others may operate for months without it. A “one-size-fits-all” approach doesn't work.

💡 Helpful tip:

Base your lubrication frequency on criticality, duty cycle, and environmental exposure. Regular condition monitoring can also help.

Why the 6 Rights matter

By applying the six lubrication rights, organisations can transform their lubrication practices from reactive to proactive. This shift not only prevents unnecessary downtime but also creates a culture of reliability and precision.

Implementing these principles doesn’t have to be difficult. With the right tools, training and discipline, every maintenance team can succeed.

Get all 6 Rights, and your machines will return the favour!

Ready to optimise your lubrication practices?

Lubretec helps companies implement best-in-class lubrication management programs. Contact us today to schedule a free consultation .