The 6 lubrication Rights &the silent phase of bearing life

the silent phase of bearing life

1. Understanding the 6 Lubrication Rights

The Six Lubrication Rights provide a clear checklist for precision lubrication:

1. The Right Lubricant

Selecting the correct lubricant for your specific application is fundamental. Factors like load, speed, temperature, and environmental conditions determine whether a grease or oil (and which formulation) is suitable. Using the wrong product can cause rapid wear, overheating, or failure.

2. The Right Time

Timely lubrication is critical. Too frequent, and you risk over-lubrication; too infrequent, and wear accelerates. Lubrication schedules should be based on operating conditions, equipment duty cycles, and historical data—not just fixed calendar intervals.

3. The Right Quantity

Over-lubricating can be just as damaging as under-lubricating. Excess grease can cause seal failures and increased operating temperatures, while too little leaves surfaces unprotected. The correct volume ensures consistent film thickness and minimises resistance.

4. The Right Place

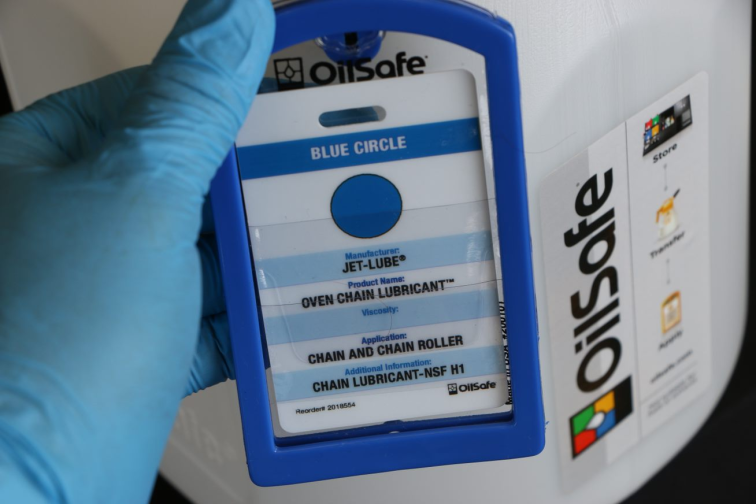

Applying lubricant to the correct point ensures it reaches the surfaces that need protection. Misapplied lubrication can lead to ineffective coverage or contamination. Clearly identified and well-maintained lube points help prevent errors.

5. The Right Method

Lubricants should be applied using the proper tools and techniques—whether manually or with automated systems. Using contaminated grease guns, incompatible fittings, or rushed practices can introduce foreign particles and compromise reliability.

6. The Right Condition

Even the best lubricant is only effective if it's clean, uncontaminated, and within spec. Storage, handling, and transfer must be carefully controlled. Condition monitoring (e.g. oil analysis, particle counting) helps verify that your lubricant is still fit for use.

First, select the right lubricant and dose. Next, deliver it precisely, then time its application correctly. Finally, monitor its effect. Following these steps avoids the common lubricant-related bearing failures: adhesive wear, fatigue spalling, cage damage, overheating, and seal leaks.

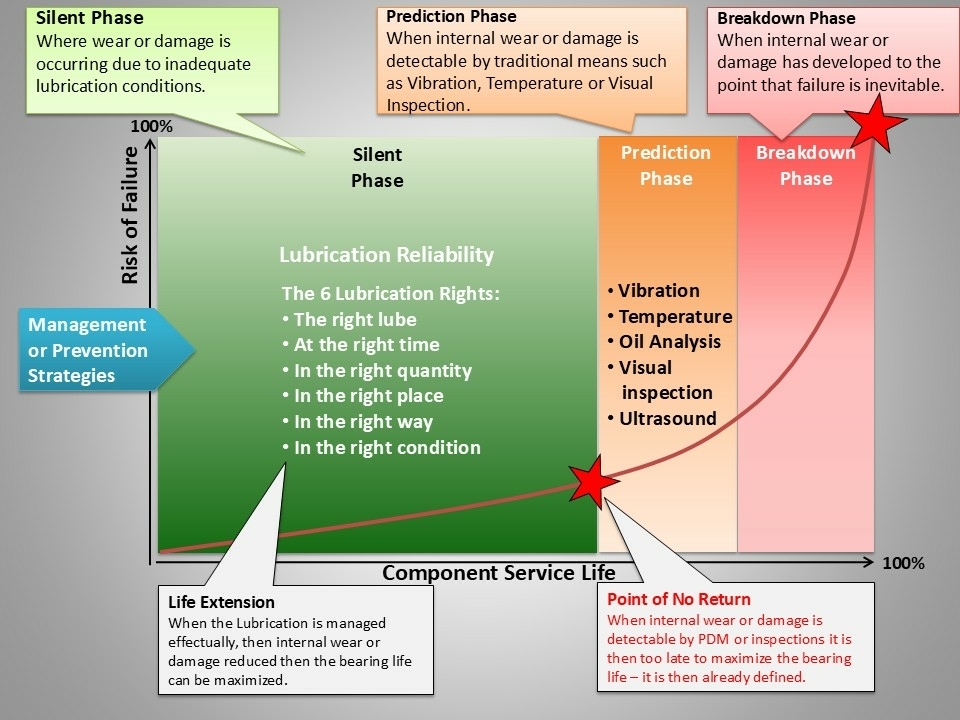

2. The silent phase of a healthy bearing

Between installation and failure, every bearing experiences a ‘silent phase’; its optimal operating period. Key characteristics during this phase include:

- Stable friction and temperature: No unexpected rises, indicating the lubricant film is intact.

- Minimal noise and vibration: No micro‑scoring or early spalling.

- Seal integrity: No lubricant leakage or contamination intrusion.

After lubrication, if the bearing enters the silent phase, evidenced by consistent readings and no irregularities, it confirms correct lubrication and installation. Maintenance shifts from reactive to predictive, focusing on timely relubrication and monitoring to avoid slipping into failure modes. When friction or vibration trends upwards, it signals deterioration of the lubricant film or onset of damage.

Why this matters

By combining the Six Lubrication Rights with awareness of the silent phase, you:

- Minimise bearing failure risk by up to 50% through correct lubrication.

- Maximise operational uptime.

- Avoid unnecessary relubrication and lubricant waste.

- Detect early signs of wear before serious damage.

Use the Six Lubrication Rights to properly select, dose, deliver, schedule, and monitor lubrication. The Silent Phase is your goal state, characterised by stable friction, temperature, sound, and seals. This combined approach ensures bearings stay in their optimal lifespan, reducing failures and maintenance costs. Thus:

- Choose the lubricant that fits your operational parameters.

- Calculate and apply the correct dose.

- Deliver it accurately into the bearing with suitable tools.

- Schedule lubrication intervals using data-driven methods.

- Monitor performance for silent-phase stability.

- Act when signs of deviation appear.

“Don’t let the silent phase take you by surprise. Listen early. Act smart. Protect your bearings, and your bottom line.”

Want to ensure your bearings run smoothly and quietly? Contact Lubretec today for expert lubrication assessment and start designing your preventive maintenance strategy now.