Contamination control built in

The system comes with a 7-micron Beta 2000-rated spin-on filter, providing industry-leading filtration during dispensing. Other filter ratings (4µ and 25µ) are available based on your lubricant cleanliness requirements.

Pre-assembled and modular

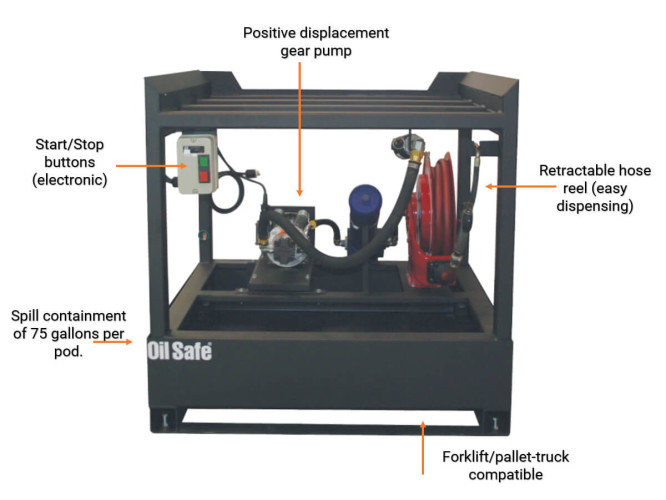

No complex installation required. After delivery, simply place the tote on the rack, connect the suction hose, power it up, and ensure proper grounding via the rear-mounted green wires.

Efficient dispensing system

Equipped with a positive displacement gear pump (3–5 GPM), 25-foot retractable hose reel with trigger dispenser, and electronic start/stop controls, the unit makes dispensing controlled and clean.

Customisable power options

Choose from electric models (110V or 240V) or a pneumatic version to match your facility's power setup.

Compact, space-saving footprint

Each unit takes up just 46" x 46" of floor space, perfect for busy industrial environments.

SPCC compliance options

Optional spill pans are available to meet spill containment regulations if needed.