See inside your machine: the power of a 3D Oil Sight Glass

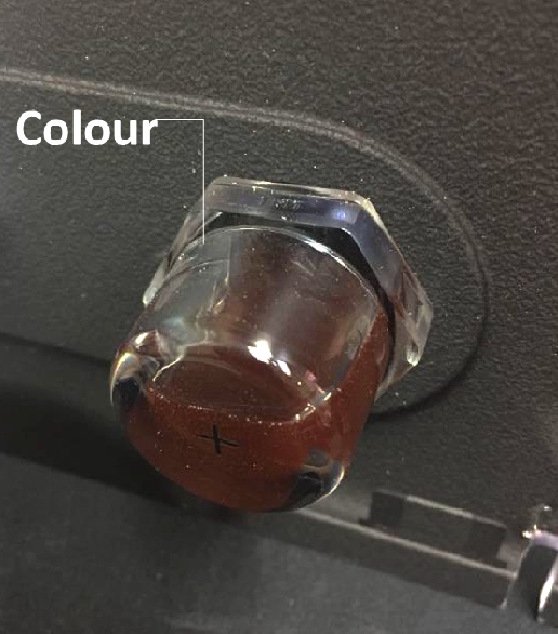

A 3D Oil Sight Glass, often referred to as a BullsEye, provides a simple yet powerful way to monitor the health of your machinery. Installed directly into a port on the sump or oil reservoir, it acts like a small, transparent window into your system—allowing operators to visually inspect oil condition and levels at a glance.

But this tool does more than just show you how much oil is present. It helps detect early signs of wear, contamination, or other issues—long before they turn into costly breakdowns. In this guide, we’ll take a closer look at how the BullsEye works, why it’s useful, and how to get the most from it.