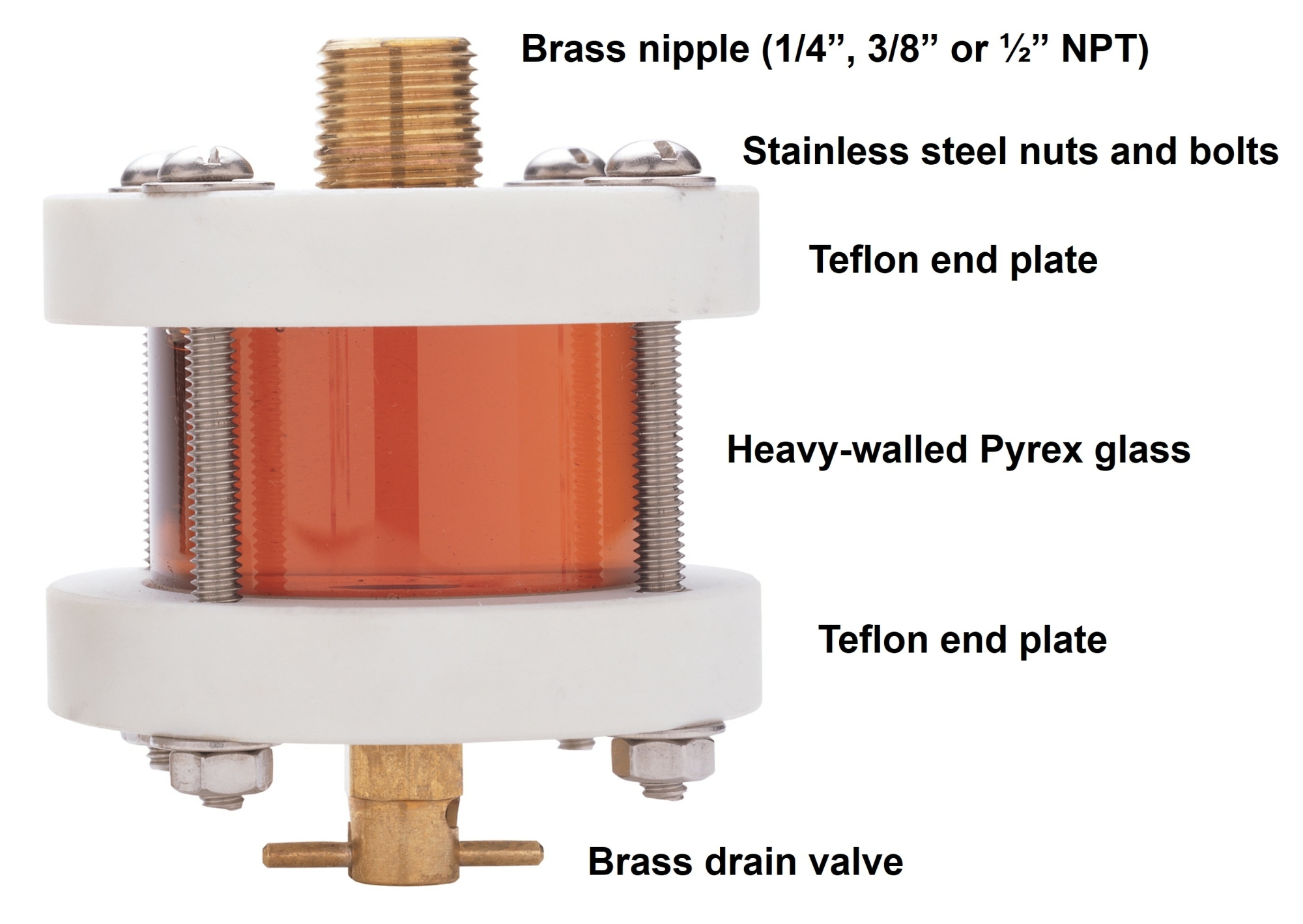

Stop guessing. Start seeing. The High Temperature Oil Sight Glass gives you a crystal clear 360° view of your oil condition even in extreme operating environments. Detect contamination early, drain free water instantly, and protect your equipment from costly downtime.

Built for harsh industrial conditions. Designed for engineers who demand reliability.