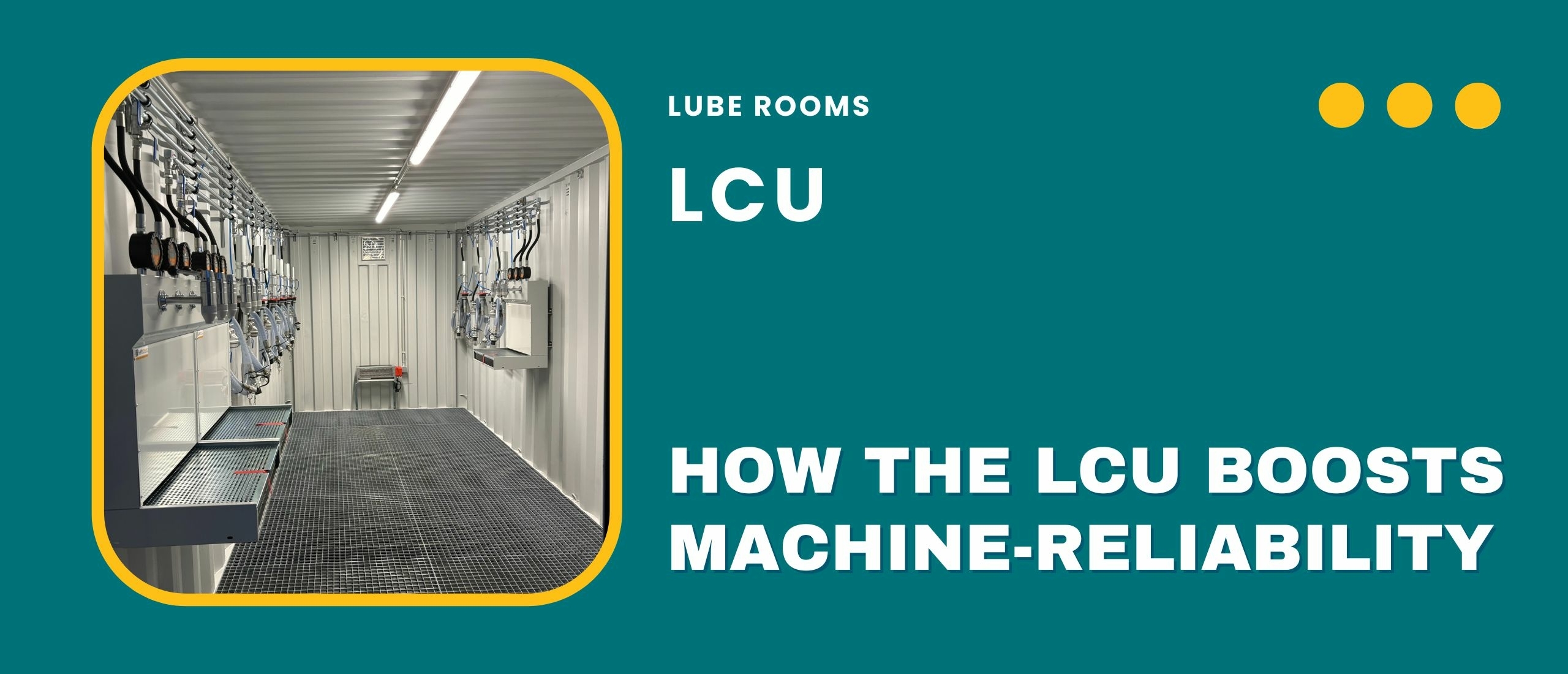

How the Lubrication Conditioning Unit boosts machine reliability

A deep dive into smart lubrication management and contamination control

In industrial environments, where every minute of downtime costs money and every component matters, the smallest details can make the biggest difference. One of those often-overlooked areas? Lubrication management. Enter Lubristation’s Lubrication Conditioning Unit (LCU)—a compact, standalone solution engineered to revolutionize how we handle, store, and apply industrial lubricants.

Whether you’re managing a single plant or multiple facilities, understanding how proper lubrication improves equipment reliability is essential. In this blog, we explore how the LCU tackles common lubrication challenges and offers measurable benefits for reliability, efficiency, and safety.

Why does lubrication management matter?

Improper lubrication is responsible for over 50% of bearing failures and a significant percentage of other mechanical breakdowns. Yet, traditional lubrication practices often rely on manual processes, unsealed containers, and inconsistent standards.

Lubrication management isn’t just about adding oil—it’s about managing contamination, preventing human error, and maintaining the right fluid condition over time. The Lubristation LCU brings this all under control in one fully equipped, customizable unit.

What is the Lubrication Conditioning Unit (LCU)?

The LCU is a self-contained, plug-and-play lubrication management hub. Built into a modified 20’ or 40’ container, it includes:

- A controlled lube room for safe storage and dispensing

- Separate pumping, filtration, and piping systems for each lubricant

- Anti-spill tap bar with color-coded hoses

- Retention floor and ventilation options

- Optional digital monitoring and consumption tracking

It’s designed to reduce contamination, prevent cross-contamination, and streamline lubrication tasks.

Reader question:

How does the LCU help control contamination?

Great question—and a critical one!

The LCU attacks contamination from several angles:

- In-line filtration down to 3 microns ensures fluids are clean before dispensing.

- Desiccant breathers block moisture and particles from entering containers.

- Sealed storage eliminates exposure to dust, humidity, or other environmental threats.

- Colour-coded, dedicated lines avoid mixing incompatible fluids.

These practices bring the ISO 4406 cleanliness level down to industry-leading standards, significantly extending component life and reducing unplanned downtime.

Eliminating cross-contamination and human error

Cross-contamination isn’t just a technical inconvenience—it can cause catastrophic equipment failures if, for example, hydraulic and gear oils are accidentally mixed. The LCU prevents this through:

- Clearly labeled and separated oil systems

- Lockable, secure storage

- Colour-coded hoses and tap handles

- Optional digital access control and logging

Maintenance teams no longer need to guess, label by hand, or rely on memory.

How does the LCU improve safety and compliance?

Handling lubricants often means exposure to slippery surfaces, harmful fumes, or unsafe lifting practices. The LCU is designed to comply with modern Safety, Health, and Environmental (SHE) standards by:

- Housing lubricants in a closed, ventilated room

- Including spill containment floors

- Providing ergonomic access with gun holder modules and workbenches

- Offering OilSafe® containers for safe transport and dispensing

This creates a cleaner, safer workspace and minimizes environmental risk.

Reader question:

Can the LCU be customized for my facility’s needs?

Absolutely. That’s one of its biggest strengths. The LCU can be tailored to your operation’s size, fluid types, and access requirements. For example:

- The 40’ container version can house up to 20 separate taps

- Optional heating, lighting, and ventilation can be installed

- Storage cabinets, open racks, and workbenches can be added

- Digital flow meters and sampling ports are available for advanced monitoring

This level of customisation means you only pay for what you need—but still get a future-proof system.

Built for sustainability and efficiency

Lubristation’s LCU isn’t just good for your machines—it’s better for the planet. Here’s how:

- Reduces lubricant waste through precision dispensing

- Prevents leaks and spills with sealed systems

- Supports clean recycling and disposal of used oils

- Cuts energy use by avoiding over-lubrication

In today’s climate-conscious industrial world, sustainable maintenance is no longer optional—and the LCU helps you get there.

Organised, accessible, and future-ready

From anti-spill valves to ergonomic design, every detail of the LCU has been designed with technicians in mind. Recent versions include:

- Gun holder modules for easy access to oil guns

- Digital monitoring options to track lubricant usage and detect anomalies

- Smart sampling ports for easy oil analysis without opening containers

This results in faster, more accurate maintenance work—and ultimately, better equipment performance.

Investing in reliability

When it comes to heavy industry, maintenance isn't just a cost center—it's a competitive advantage. The Lubristation LCU is more than a product; it’s an investment in machine reliability, technician safety, and operational efficiency.

Whether you're dealing with premature bearing wear, frequent oil changes, or just looking to modernise your maintenance processes, a smart lubrication strategy—anchored by the LCU—can unlock real, measurable improvements.

Want to see how the LCU could work for your site?

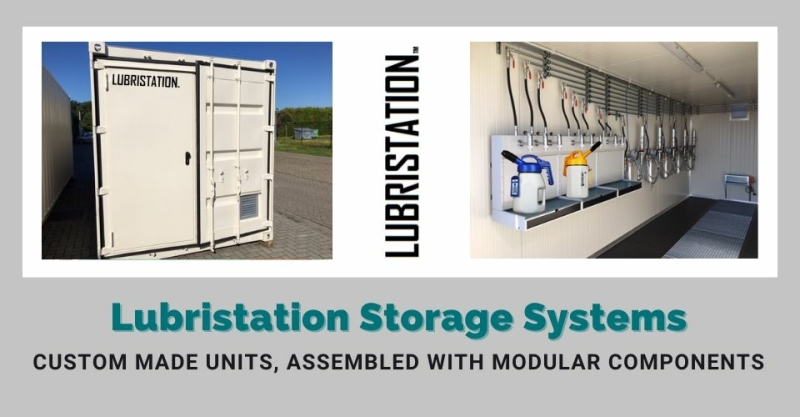

Additional note: Lubristation custom options and components

Tailor your Lubrication Conditioning Unit to meet your operational needs

Every industrial site is unique, and so are its lubrication requirements. Lubristation understands this reality and offers a comprehensive range of customisation options for the Lubrication Conditioning Unit (LCU). These modular upgrades allow you to configure the unit for maximum efficiency, safety, and convenience.

Below is an overview of available components to enhance your LCU setup:

🔹 Dual ventilation system

Improve airflow and maintain a stable environment

- Two ventilation grilles (300 x 300 mm)

- Installed diagonally below the door on the centre of the back wall

- Enhances air circulation to manage humidity and temperature

Part # LU-LCU020DV

Double ventilation (300x300)

🔹 Extra emergency access door

Ensure safety and facilitate easy movement

- Additional walking door integrated into the container structure

- Placement options: in the main container door, side wall, or back wall

- Available as single or double door configurations

- Improves accessibility and emergency egress

Part # LU-LCU020D01

Extra emergency walking door for easy access

🔹 PU-insulated interior lining

Optimise thermal control inside the unit

- 40 mm polyurethane insulation

- Coated steel interior on walls, ceiling, and doors

- Provides effective insulation against both heat and cold

- Ideal for temperature-sensitive lubricants

Part # LU-LCU020ISO

Internal insulation PU 40 mm

🔹 Drive-on ramp

Simplify handling of heavy drums

- Ramp designed for trolleys carrying 200-litre oil drums

- Enables safe and efficient movement into the container

- Reduces manual lifting and improves workflow

Part # LU-LCURMP

Drive on ramp for trolleys

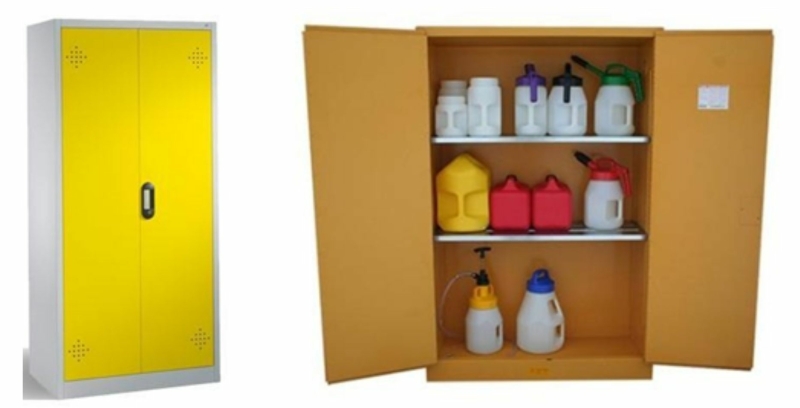

🔹 Closed storage cabinets with retention shelving

Organised and spill-protected storage

- Standard cabinet includes 5 retention shelves

- Designed to prevent leakage and simplify clean-up

- Not fireproof, but custom dimensions and additional shelves available

- Keeps tools, containers, and smaller items neatly arranged

Part # SK-0195100

Closed cabinets with retention shelves

🔹 Open storage rack for OilSafe® containers

Smart storage for frequently used lubricants and tools

- Compatible with OilSafe® transfer containers (available in 1.5L to 10L sizes)

- Supports all five lid types: stumpy spout, stretch spout, mini spout, utility, and storage lids

- Includes room for small lubrication tools

- Standard size: 100 x 50 x 200 cm

- Optional add-on racks and extra retention shelves available

Part # MT-920157705

Open Racks

Open Racks

Why these options matter

Adding these features doesn't just make the LCU more versatile—it helps align your lubrication setup with best practices in safety, contamination control, and maintenance efficiency. Whether you're expanding capacity, enhancing safety, or improving usability, these components offer smart, modular upgrades to support your goals.

Want help choosing the right configuration for your environment?

and we’ll guide you through the customisation process.