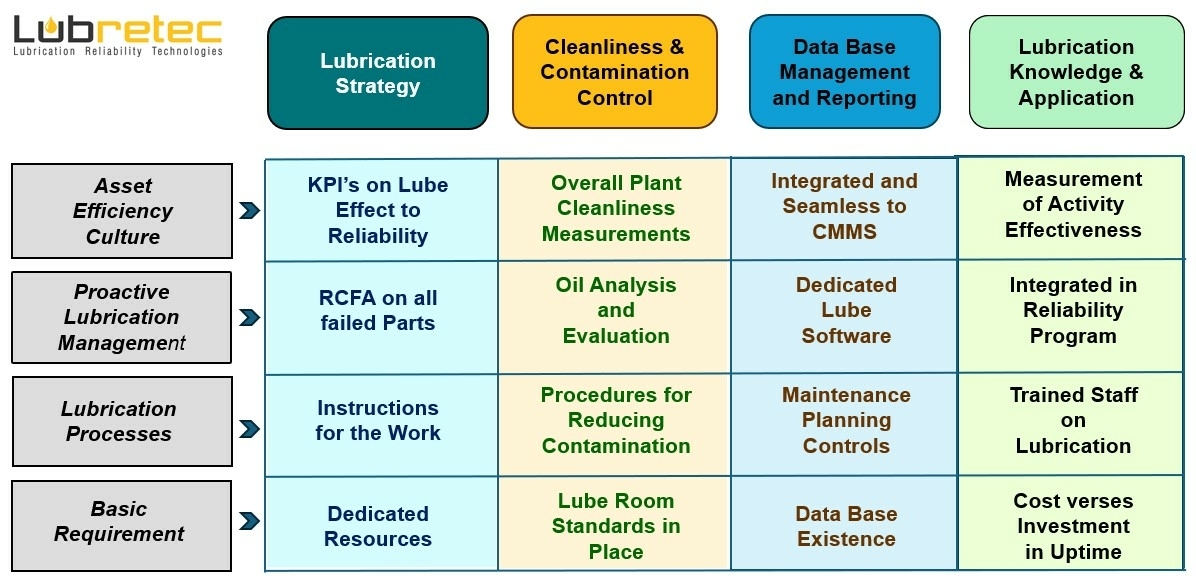

Establishing the foundation for Lubrication Excellence

To build a world-class reliability programme, you must first understand your current position. A Lube Assessment & Benchmark is the first, and arguably the most critical step in improving the efficiency, safety, and reliability of your equipment.

At Lubretec, we conduct in-depth lubrication assessments that go beyond surface-level checklists. Our methodology is built on real-world experience in diverse industrial environments, and aligns with global best practices in Lubrication Reliability.