Step 4 - Monitoring cleanliness: go beyond what the eye can see

Explanation of how and why to monitor cleanliness levels with particle counters or oil analysis as part of an effective lubrication reliability programme:

Visual checks are not enough when it comes to lubricant cleanliness. Most harmful contaminants—such as metal particles, silica dust, and soot—are microscopic and invisible to the naked eye. That’s where particle counting and oil analysis come in. These methods provide measurable, actionable data on the condition of your lubricants and the overall health of your machinery.

What is a particle counter?

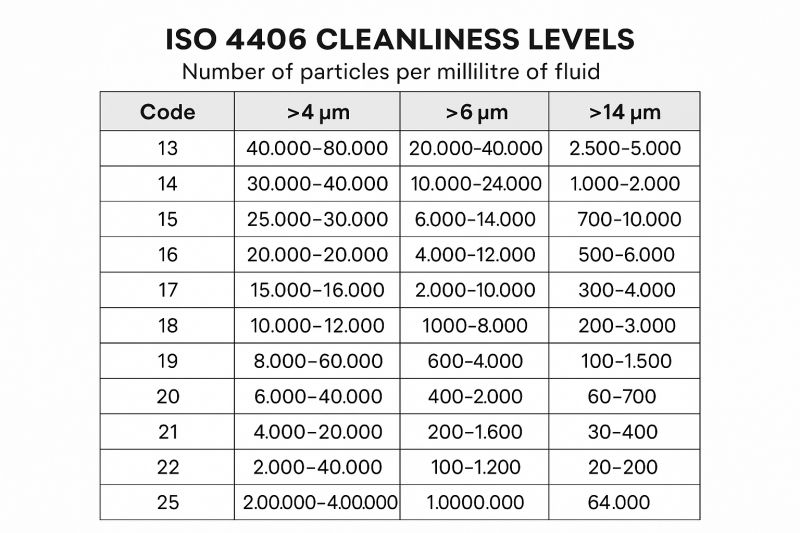

A particle counter is a tool that measures the size and number of solid particles in a sample of oil. It classifies particles according to standard cleanliness codes—most commonly the ISO 4406 standard.

ISO 4406 expresses cleanliness as three numbers (e.g. 19/17/14), representing the quantity of particles larger than:

- 4 microns

- 6 microns

- 14 microns

The lower the numbers, the cleaner the oil.

Why use particle counters?

- Detect early-stage wear before it leads to failure

- Verify filtration performance during oil transfer or circulation

- Set and enforce cleanliness targets for different equipment types

- Support predictive maintenance by tracking trends over time

On-site portable particle counters are ideal for quick checks during oil changes, while inline particle counters can be installed for continuous monitoring of high-value systems.

What is oil analysis?

Oil analysis is a laboratory-based diagnostic tool that examines multiple properties of a lubricant, including:

- Particle count and types of wear metals

- Water and moisture content

- Oxidation and additive depletion

- Viscosity and contamination levels

- Acid number (AN) and base number (BN) for degradation tracking

Lab analysis offers a more comprehensive view than a particle counter alone, making it ideal for critical equipment and long-term monitoring.

Reader question: “How often should I monitor oil cleanliness?”

The frequency depends on the criticality of the machine, environmental conditions, and lubricant life cycle. As a general rule:

- High-value or high-speed equipment: Monthly or even continuous monitoring

- Standard industrial machines: Every 3–6 months

- Food-grade or safety-critical applications: Aligned with IFS or ISO 22000 schedules

Always analyse after filtration, after top-ups, and during suspected contamination events.

Set cleanliness targets by equipment type

Each machine has its own tolerance for contamination. Use a lubricant supplier or reliability engineer to define target ISO 4406 codes for your equipment. For example:

- Hydraulics: ISO 17/15/12 or cleaner

- Gearboxes: ISO 20/18/15 or better

- Circulating systems: ISO 18/16/13

Key takeaway

Monitoring lubricant cleanliness isn't just good practice—it’s an essential part of proactive maintenance. With tools like particle counters and regular oil analysis, you gain visibility into the health of your lubrication system, allowing you to act before wear becomes failure.