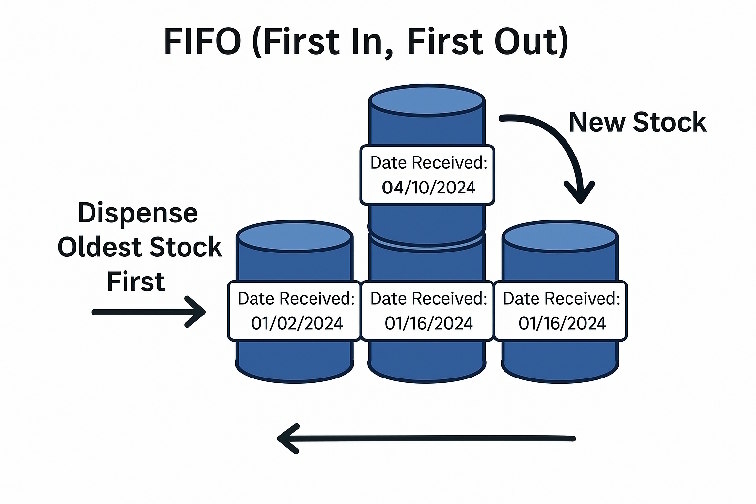

FIFO (First In, First Out)

FIFO, or First In, First Out, is an inventory management method used to ensure that the oldest stock in storage is used or sold before newer stock. In lubrication management, FIFO helps maintain oil and grease quality by preventing long-term storage that can lead to degradation.

Purpose

The main goal of FIFO is to preserve lubricant performance by minimising the time between delivery and use. This reduces the risk of expired or degraded lubricants being applied to machinery, which can cause equipment damage and reduce reliability.

How It Works

- Receiving – When new lubricant deliveries arrive, they are placed behind or beneath existing stock so that older stock remains at the front or on top.

- Labelling – Each container is marked with a date of receipt to make age tracking easy.

- Dispensing – Maintenance staff always select the oldest stock first, following the date order.

Benefits in Lube Rooms

- Prevents lubricant shelf-life expiry.

- Reduces waste from out-of-date products.

- Ensures consistent lubricant performance in line with manufacturer specifications.

- Supports ISO 4406 cleanliness goals by avoiding deterioration during storage.

Example in Practice

A lube room stores multiple drums of hydraulic oil. When a new shipment arrives, the existing drums (received two months earlier) are placed in front. Staff always use these first, ensuring no drum exceeds its recommended storage life.