What is the Lubristation™ S?

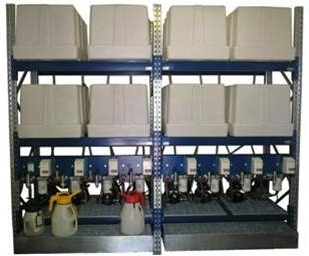

The Lubristation™ S is a stand-alone lubrication module - a compact, self-contained unit where all essential components are built into a single enclosure. Equipped with HDPE tanks, electrical pumps, three-way filtration, and retention features, it delivers a complete storage, conditioning, and dispensing solution designed for small to medium workspaces.

This integrated approach ensures lubricants are kept clean, protected, and ready for safe dispensing - even where space is at a premium.

Why choose a compact stand-alone lubrication unit?

In confined environments such as workshops or small lube rooms, contamination and clutter can become serious issues. The Lubristation™ S offers a compact footprint while maintaining best-practice lubrication reliability. Key benefits include:

- Optimised use of space with horizontal HDPE tanks

- Built-in filtration to maintain cleanliness (minimum three-stage filtration loop)

- Safe, spill-free dispensing with dedicated pump and tap system

- Reduced risk of error and improved efficiency in high-pace environments

How does the Lubristation™ S work?

How does the Lubristation™ S work?

Here’s the process overview:

Storage – Lubricants reside in horizontal HDPE tanks within the enclosed unit.

Conditioning – The system continuously filters oil using built-in three-way filtration and protection mechanisms like Lubesec breathers.

Dispensing – Clean lubricant is distributed via electric pumps and directed through self-closing taps—ready to dispense into OilSafe® containers.

Key features of the Lubristation™ S

Compact integrated design – Tank, pump, filtration, and tap in one sleek module.

HDPE construction – Durable, corrosion-resistant, and translucent for level checks.

Three-way online filtration – Purifies lubricants during transfer and dispensing.

Electrical pump system – Efficient and safe operation.

Additional options – Integration of consumption meters, OilSafe identification, and retention tanks.

High cleanliness standards – Designed using lubrication-reliability best practices.

Where is Lubristation™ S most effective?

Where is Lubristation™ S most effective?

Ideal for environments that need efficient, clean lubrication with minimal footprint, including:

Workshops and repair facilities

Small manufacturing or assembly lines

Compact lube rooms and maintenance areas

Any site where space, cleanliness, and speed are priorities

Technical specifications (typical configuration)

Tank material: HDPE, transparent for easy level monitoring

Pump type: Electric

Filtration: Always active three-way system

Optional add-ons: Retention tanks, metering, OilSafe ID, etc.

Dimensions: Designed to optimise floor space (approx. 3 lubes per m²)

(Exact specs vary per configuration; see the data sheet for full details.)

Benefits at a glance

Saves valuable floor space while delivering full lubrication control

Keeps lubricants free from contamination through continuous filtration

Enhances lube room safety and cleanliness

Offers modular expansion and best-practice compliance

Streamlines maintenance and reduces downtime

Related resources

📄 Lubristation overview page – Learn about the full Lubristation product family and how each model supports best-practice lubrication.

📄 OilSafe® lubrication transfer solutions – Discover compatible transfer containers and accessories for complete contamination control.

Make lubrication effortless

Contact Lubretec to specify your

Lubristation™ S module today.