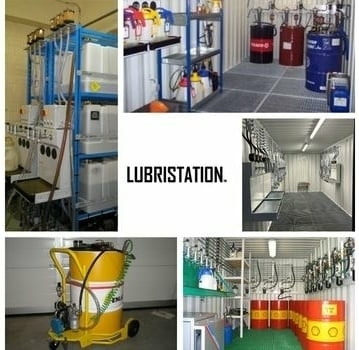

The Lubristation™ family is Lubretec’s innovative range of systems for the storage, conditioning, and distribution of lubricants. Each unit is custom-built using modular components, designed specifically around the client’s operational requirements.

When designing a Lubristation™ system, we consider:

- Location and format – compact or extended, fixed installation or mobile unit

- Lubricant type and quantity – including oil viscosity and variety of products used

- Consumption and packaging – from bulk supply and 200-litre drums to small containers and cans

- Budget and specification level – from essential configurations to fully equipped “best practice” systems with all available options