The Essential Role of Desiccant Breathers

Desiccant breathers go beyond basic vent caps by filtering incoming air and removing moisture before it enters oil-filled reservoirs, gearboxes or storage tanks. They prevent water and particle contamination, extend equipment life, reduce maintenance costs and improve reliability — whether for hydraulics, transformers or storage systems. Regular replacement or recharging of the desiccant and correct sizing make them effective tools for contamination control and long-term performance.

Introduction

When you think of industrial equipment, whether hydraulic systems, transformers or storage tanks, you likely focus on robust metals, strong seals and fluid-carrying capacity. But one frequently overlooked component can make or break the longevity and performance of such systems: the breather.

Not just any breather though; we are talking about desiccant breathers, which not only allow air exchange but actively filter and dry it. In many installations, standard vent caps are simply not enough. Moist air, dust and tiny particulates easily enter every time a system “breathes”, and over time these contaminants degrade lubricants, corrode components, and lead to premature failure.

That’s why desiccant breathers deserve a critical place in your maintenance and reliability strategy. This guide explores how they work, why they matter, how to choose them and how to maintain them for optimal results.

What is a desiccant breather, and how does it differ from a vent cap?

The limitations of standard vent caps

Many original-equipment manufacturers (OEM) equip machines with simple vent or fill caps. These allow air to enter or exit as fluid levels change or as the equipment heats and cools.

However, such caps offer minimal contamination control. They may keep out large debris, but they do little to stop fine dust, moisture or vapour from entering, often allowing particles smaller than one-tenth of the thickness of a human hair to pass into the system.

Once inside, these contaminants begin to erode gears, bearings and valves; introduce water into lubricants; accelerate corrosion; and compromise the integrity of the fluid and components.

Vent cap

Vent cap

What a desiccant breather does differently

A desiccant breather replaces the standard vent cap or vent port and adds active protection:

- Incoming air is drawn through a first-stage filter that removes solid particles.

- The air then passes through a desiccant medium (typically silica gel) that absorbs water vapour, trapping moisture before it enters the reservoir or gearbox.

- Some designs also include a secondary filter, further ensuring that no harmful particles or moisture reach internal fluids.

In effect, the system no longer just “breathes”; it breathes clean, dry air, reducing the risk of moisture- or dirt-induced damage.

Why desiccant breathers are essential

Moisture protection and corrosion prevention

Moisture in hydraulic fluid or lubricating oil is a primary culprit in corrosion, additive depletion and oil degradation. In gearboxes or transformers, water can severely impair function; from compromised lubrication to increased risk of sludge formation or oxidation.

By removing water vapour from incoming air, desiccant breathers keep internal humidity low, even during frequent air exchanges due to temperature changes or fluid movements.

Contamination prevention - dust, particles and debris

Dust, dirt and microscopic particles in ambient air may seem harmless, but when they enter a hydraulic reservoir or gearbox, they accelerate mechanical wear: grinding against bearings, eroding sealing surfaces, clogging filters, and degrading fluid quality.

Desiccant breathers with fine-micron filtration (e.g. 2–3 µm) act as the first line of defence, blocking even very small contaminants from entering the system.

Improved equipment performance and extended life

With dry, clean air ingress, lubricants stay cleaner longer; gears and bearings remain protected; corrosion is diminished; and overall wear is delayed. The result: fewer breakdowns, longer service intervals and extended equipment lifespan.

Many operators observe that a large fraction of lubricant contamination - and consequent failures - originates from outside the system. Using desiccant breathers as a contamination-exclusion strategy often costs far less than frequent fluid changes or repairs.

Reduced maintenance costs and lower total cost of ownership

By preventing contamination and reducing wear, desiccant breathers cut down the frequency of oil changes, component replacements, filter replacements and unscheduled maintenance. Over the long term, this yields significant cost savings compared to traditional venting solutions.

Versatility across industries and applications

Desiccant breathers are not limited to hydraulic systems. They are widely used in transformers, lubrication systems, gearboxes, fuel or fluid storage tanks, drums, resin systems - across industries like oil and gas, petrochemical, power generation, manufacturing, marine and more.

Whether indoors or outdoors, even in humid or harsh environments, they offer reliable protection.

How desiccant breathers work - A closer look

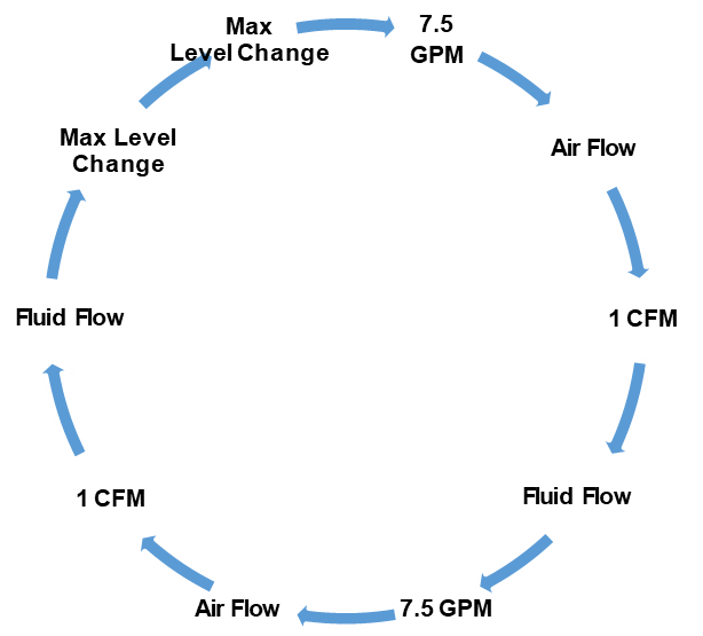

Here is a simplified step-by-step flow of what happens inside a desiccant breather:

- When oil or fluid level changes, or when internal pressure varies due to thermal fluctuations, the system draws in ambient air through the breather.

- The incoming air first passes through a fine particulate filter (e.g. 2–3 µm), trapping dust, dirt and solid contaminants.

- Then it flows through a desiccant medium (commonly silica gel), which adsorbs moisture and significantly lowers the air’s humidity before it enters the reservoir.

- Some designs include a second filtration stage after the desiccant, to catch any remaining particulates or oil mist.

- When the system vents air out (during pressure build-up, fluid heating, or normal operation), that outgoing air also passes through the breather — and any moisture or contaminants are again trapped by the desiccant or filters.

Many breathers include a colour-change indicator - typically the silica gel shifts colour when saturated (e.g. from gold to dark green), signalling it’s time to replace or recharge the cartridge.

Selecting and installing a desiccant breather - What to consider

To get the most from a desiccant breather, it’s not enough to simply bolt one on. Proper selection and installation are vital. Key factors to evaluate:

- Airflow rate (CFM capacity): The breather must support the maximum expected air exchange rate of the reservoir or gearbox; otherwise pressure imbalances or vacuum issues may occur.

- Reservoir capacity and head-space dynamics: Larger fluid volumes or systems with frequent fluid level changes require breathers with larger desiccant beds or higher capacity to avoid rapid saturation.

- Environment and exposure: For harsh conditions - high humidity, dust, rain, salt air (marine) - choose breathers with robust housings, proper sealing, and perhaps additional features like sealed caps or flame arrestors.

- Maintenance accessibility: Prefer breathers with easily replaceable cartridges and colour-change indicators; that simplifies regular checks and avoids neglect.

- Check valves or sealing mechanisms (if applicable): In some systems, hybrid breathers with bladders and one-way valves can reduce unnecessary air exchange and prolong breather life — especially useful in stable, low air-exchange environments.

Maintenance and Best Practices

Even the best breather will fail if ignored. To keep equipment safe and efficient:

- Inspect the breather regularly - at intervals recommended by the manufacturer.

- Monitor the desiccant cartridge: check the colour indicator for saturation and replace or recharge when colour changes.

- Replace or clean filters as needed; clogged filters reduce airflow and can cause pressure issues.

- Ensure the breather remains properly seated and sealed; loose or damaged installations expose the system to moisture and particulates.

- Document maintenance actions and integrate breather checks into routine service schedules - part of a robust contamination-control and lubrication-management programme.

Common Pitfalls and Misconceptions

- “Vent caps are enough.” As explained earlier, simple vents offer minimal contamination control and do not address moisture.

- “Breathers are only needed outdoors.” Even indoor installations are susceptible to humidity, dust or internal moisture formation — so desiccant breathers often benefit indoor hydraulic or lubrication systems too.

- “Desiccant breathers are maintenance-free.” Not so: desiccant will saturate over time, filters will clog, and efficiency drops - requiring timely replacement or recharge.

- “One size fits all.” Breather sizing and capacity must match the airflow and reservoir dynamics of each system; a mismatch can do more harm than a simple vent.

Conclusion

Desiccant breathers are far from optional accessories - they are essential safeguards for any system that stores or circulates fluids in open head-spaces, such as hydraulic reservoirs, gearboxes, transformers, drums or storage tanks. By filtering out particulate contaminants and removing moisture from the air, they maintain lubricant integrity, prevent corrosion, reduce wear, and significantly extend equipment life.

The benefits are clear: fewer breakdowns, lower maintenance costs, longer service intervals, and improved reliability. But to reap these benefits, you must choose the right breather for your system, install it correctly and maintain it diligently.

If you are still relying on standard vent caps - or haven’t checked your breathers in a while - now is the time for a proper breather audit.

For help selecting the right breather, sizing correctly, or establishing a maintenance schedule: contact us or subscribe for more technical guidance.