In industrial environments, unplanned downtime is expensive. With the Condition Monitoring Pod® (CMP®), you can spot early warning signs before they escalate into serious mechanical failures. This robust and highly visible inspection pod allows for daily monitoring of oil and machine health—saving you time, money, and maintenance headaches.

The CMP®

The CMP®

Your essential tool for real-time machinery health checks

Your essential tool for real-time machinery health checks

What is the Condition Monitoring Pod® (CMP)?

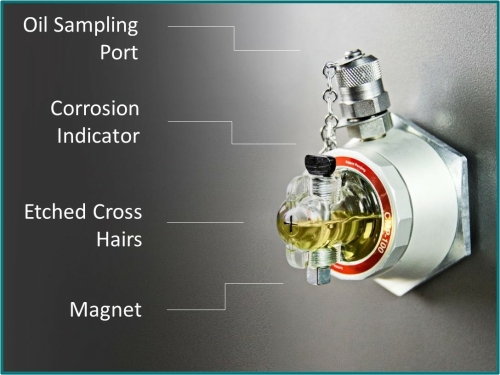

The CMP is a multi-parameter visual inspection tool that mounts directly onto your machinery’s oil level port. Engineered for reliability, it allows for real-time assessment of:

- Oil level, colour, and clarity

- Foam and aeration

- Wear debris detection

- Signs of corrosion and varnish

All of this can be checked without interrupting operations, making the CMP a must-have for proactive maintenance routines.

Why is visual oil inspection important?

Why is visual oil inspection important?

Lubrication is the lifeblood of mechanical equipment. When oil degrades or becomes contaminated, damage can occur silently. With the CMP, you can:

- Detect issues like foaming (which can signal aeration or overfilling)

- Identify water contamination early, before rust takes hold

- Spot wear particles from failing bearings or gears

- Monitor for varnish, which leads to sticky valves and sluggish performance

By catching these signals early, you're not just monitoring—you’re preventing costly breakdowns.

What makes the CMP® more reliable than other sight glasses?

Many standard sight glasses fail under harsh conditions. The CMP stands out with:

- Tritan® sight glass, nearly indestructible and crystal clear

- Viton® O-rings, known for high chemical resistance and sealing reliability

- Anodised aluminium body, corrosion-resistant and durable

- Built-in neodymium magnet, for capturing ferrous particles

- Stainless steel pilot tube and reducer, ensuring lasting performance

It's also compatible with both mineral and synthetic oils, and performs in extreme temperatures from -40°C to 93°C.

Where should I install the CMP on my machine?

Where should I install the CMP on my machine?

Install the CMP at a port on the centreline of the oil level—never below it or on a pressurised system. This ensures you get an accurate reading of oil level and condition under operating conditions.

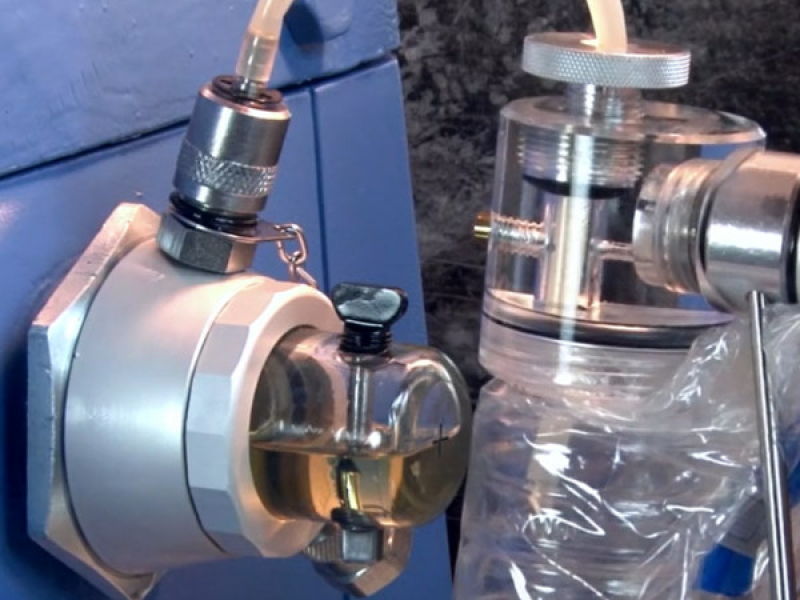

Follow these essential installation steps:

- Lower oil level before mounting

- Install thread reducer using thread sealer

- Align and bend pilot tube to sample the correct area

- Mount CMP tightly, avoiding over-tightening the locknut

- Refill oil, ensuring the level matches the crosshair in the sight glass

Detailed installation instructions come with the product, or can be downloaded here:

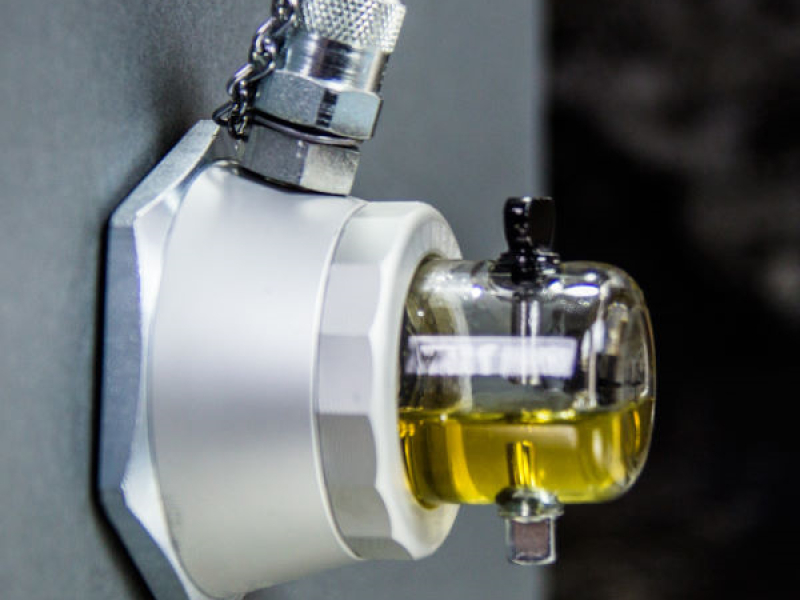

What should I check daily?

A daily glance at the CMP can reveal:

- Colour changes – Dark oil may indicate oxidation

- Clarity – Cloudy oil often means contamination or water

- Foam or bubbles – A sign of aeration, potentially from a failed seal

- Debris – Look for metallic particles on the internal magnet

- Corrosion indicator – If discoloured, water may have breached your lubricant

You can also pull a lab sample using the built-in valve for a deeper analysis.

Who can benefit from using the CMP?

The CMP is ideal for maintenance teams in industries like:

- Manufacturing

- Power generation

- Mining

- Marine

- Oil and gas

If your operations involve pumps, gearboxes, vertical motors, or hydraulic reservoirs, the CMP can quickly become one of your most valuable predictive maintenance tools.

Is the CMP safe for all machines?

Not all.

Here's when not to use it:

- On pressurised systems

- On machines with extreme temperature exposure beyond -29°C to 94°C

- With oils incompatible with Viton® or PMMA®

- In high-vibration or mobile machinery

Always refer to the user manual and ensure correct installation for safe and effective operation.

CMP Accessories

Protective cover for CMP

Magnetic Plug 3-Pack

Steel corrosion indicator

Copper corrosion indicator

Standard flow sampling probe

For attaching vacuum sampling pump to standard flow sampling valve. Specs: Sampling probe with barb for 0.17” inside diameter tubing; 6” length of LLDPE tubing included

CMP sight glass replacement kit

CMP sight glass replacement kit

The CMP’s Sight Glass is made of TritanTM copolyster, one of the most impact and chemically resistant materials available. However should the impossible happen and the CMP’s sight glass need to be replaced, this kit will do the job. Included: Steel corrosion indicator, Magnetic plug, O-ring grease, Tritan™ sight glass with O-ring and installation instructions

Tube bender

Choose your exact pilot tube bend locations and angles to best place the tip of the pilot tube within your machine. It is designed to work with the Condition Monitoring Pod and Hub pilot tubes. Specs: For 3/16”, 1/4” or 5 mm diameter tubing

Standard flow oil sampling kit

Standard flow oil sampling kit

Draw representative oil samples with our Sampling Kit. The kit is designed to work with the Condition Monitoring Pod and the Hub (standard flow sampling probe). Specs: Vacuum pump, 6’ LDPE tubing, standard flow sampling probe, 1 (16 oz) purge bottle, 4 (4 oz) sample bottles

FAQ about the CMP

FAQ - CMP

What is a Condition Monitoring Pod (CMP)?

The CMP is a multi-parameter oil condition monitoring device for your machine's oil level port. It can detect oil levels, debris, air, moisture, oil degradation, and corrosion. Its convenient built-in sampling valve also allows for live zone sampling on demand. The Condition Monitoring Pod is also known as the CMP or the Pod for short.

What machine port hole diameters can be used with the CMP?

The CMP is currently designed for the following port sizes. You may use additional bushings to expand the thread diameter but NOT reduce it. Reducing the diameter will cause errors in oil level measurement.

NPT models are available in 1/2", 3/4", 1", 1-1/4", 1-1/2", 2”.

BSPP models are available in 1/2", 3/4", 1”, 1-¼”, 1-½”, 2”.

Metric models are available in M20x1.5, M22x1.5, M24x1.5, M26x1.5, M27x1.5, M30x2.0, M33x1.5, M33x2.0, M36x1.5, M42x1.5, M42x2.0,

How far below the oil-level should the tip of the pilot tube be located?

During standard operating conditions, the tip of the Pilot Tube should never rise above the oil level. If the level is unknown, it is best to bend the Pilot Tube as far down as possible without interfering with internal machine components, touching the casing walls, or hindering installation.

What is the locknut for?

The Locknut secures the Sight Glass against the Pod Body. It can be loosened to rotate the Sight Glass during oil inspection, but it should always be retightened to prevent the Sight Glass from falling out.

Why do I need corrosion indicators?

The Corrosion Indicators are effective for identifying corrosive conditions inside your machine. This enables corrective action to be taken before irreparable damage occurs to the machine.

Corrosive conditions can exist due to one or more of the following:

1.) The depletion of the oil’s anti-corrosion agents due to oil degradation

2.) The presence of corrosive organic acids due to oxidation of the oil

3.) The presence of acids, water, salt, and bacteria from the environment.

Corrosive conditions can damage machine surfaces, including steel and cupric metals like copper, brass, and bronze. When this happens, there is no easy way to determine the onset of corrosion within your machine, which risks complete failure.

How do the corrosion indicators work?

The Indicators are exposed to the oil and the air above the oil, which makes them prime targets for corrosion. They are also made of metal alloys that are vulnerable to corrosion. If there are corrosive conditions inside your machine, the indicators will provide an early indication of this simply by looking at them through the Pod Sight Glass. Signs of corrosion include discoloration, speckling, flaking, and material loss.

A simple tool with powerful insight

The Condition Monitoring Pod® isn’t just another sight glass. It’s a rugged, all-in-one inspection device that empowers you to make smarter maintenance decisions. With a quick glance, you can spot early signs of trouble, take preventive action, and keep your operations running smoothly.