Contamination during oil storage isn’t just a nuisance—it leads to degraded product quality, reduced additive effectiveness, and costly filtration. With fluctuating temperatures causing pressure changes, even well-sealed drums can become vulnerable to moisture and particulate ingress. That’s where Air-Lock® comes in. Engineered with precision and tested for reliability, Air-Lock ensures your stored oil remains clean, stable, and protected.

Air-Lock

Air-Lock

Keep your oil drums contaminant-free with Air-Lock®

Keep your oil drums contaminant-free with Air-Lock®

Why do oil drums need pressure protection?

Why do oil drums need pressure protection?

Oil drums may seem sealed tight, but they’re not immune to environmental stress. As temperatures rise and fall, the air inside the drum expands and contracts. This pressure fluctuation can draw in contaminants through the smallest of breaches in the seal. Over time, even minimal contamination can:

- Degrade additive packages

- Accelerate oxidation

- Increase filtration demands

- Lead to premature equipment wear

Air-Lock® creates a positive pressure barrier in the drum headspace, effectively preventing outside air—and its contaminants—from entering.

How does Air-Lock® work?

How does Air-Lock® work?

Air-Lock® is a patented pressure device that replaces the standard 2" bung plug on your oil storage drum. Its internal mechanism is designed to:

- Maintain a slight positive air pressure (~2.5 psi)

- Prevent backflow of air, moisture, and dust

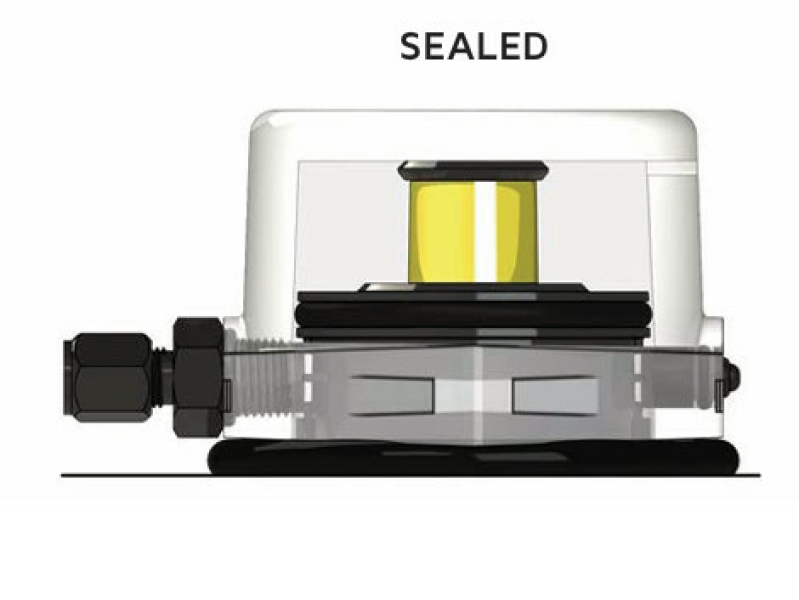

- Visibly indicate pressure status with a yellow fluorescent marker

The pressure indicator rises as internal pressure increases and stays visible when the drum is sealed. This instant visual feedback allows operators to quickly confirm the integrity of the drum’s protection—no guesswork involved.

How do I install Air-Lock on my oil drums?

Installation is straightforward, even in field conditions. Here’s a step-by-step guide:

- Remove the existing 2” bung plug from the drum.

- Install Air-Lock by hand-tightening or using a wrench until the Viton® O-ring is fully compressed. Avoid overtightening.

- Connect an air compressor (regulated below 100 psi) to the built-in Schrader valve.

- Pressurise until the yellow indicator rises and stabilises at ~1.5 psi.

- Stop after 5 seconds once the indicator stops moving—your drum is now sealed.

- Attach the included identification decal to the drum lid for easy reference.

Always ensure the ¾” plug is also securely in place.

How do I know if my drum is still sealed?

It’s simple. Look for the yellow indicator:

- • Visible indicator: Your drum is sealed and maintaining pressure.

- • Indicator not visible: The pressure has dropped—check for leaks or repressurise.

Routine checks are quick and easy, making Air-Lock® a highly user-friendly solution for daily operations.

Built for rugged storage conditions

Air-Lock® is designed for long-term outdoor storage and a wide range of operating conditions:

- Temperature tolerance: –40°F to 200°F (–40°C to 93°C)

- UV resistant: For extended sun exposure

- Chemical resistant: Compatible with most mineral and synthetic oils

- Durable materials: Tritan®, Viton®, stainless steel, PA6 nylon—engineered for performance

This makes Air-Lock ideal for industrial, agricultural, marine, and transport applications.

FAQ about the Air-Lock

FAQ - Air-Lock

What is Air-Lock?

Air-Lock protects oil drums against contaminant ingression during storage. Air-Lock's patented design prevents contamination by increasing the headspace air pressure which acts as a barrier against contaminants. Air-Lock also features a yellow fluorescent indicator to indicate a good seal and that pressure is maintained.

What safety precautions should I take?

While Air-Lock® is safe and easy to use, observe the following:

• Never open a sealed drum—even if the indicator is not visible—until it is depressurised.

• Do not block the relief valve or vent.

• Avoid using high-pressure water or incompatible chemicals for cleaning.

• Never use the Schrader valve as leverage for tightening.

The integrated safety relief valve opens at 4.0 psi to prevent over-pressurisation.

Can I use Air-Lock with any type of drum?

Air-Lock® is specifically designed for steel drums with a standard 2" NPT thread. The drum must be in good condition and capable of holding slight pressure. It is not compatible with:

• Desiccant breathers

• Filter carts

• Non-steel or damaged drums

• Environments with extreme temperature fluctuations beyond 75°F (24°C)

Can I use nitrogen gas with Air-Lock?

Yes! In fact, we think of Nitrogen as the platinum standard for pressurizing Air-Lock. Nitrogen is more resistant to fluctuations in temperature than regular air, making it the perfect upgrade to complement the Air-Lock system.

Don't worry, regular air provides all the protection you need from contaminants. It's the pressure that protects, not the composition of the gas.

Can Air-Lock be used outside?

Yes! Airlock is made of the same robust and durable Tritan material used in all of Luneta's sight glasses. Tritan® has UV stabilizers that protect against sun exposure. Tritan can withstand temperatures from -40°F to 200°F. (-40ºC to 93ºC)

Do the threads require Teflon tape?

Thread sealing tape or paste is not recommended as it may contaminate fluid in the barrel. Air-Lock is fitted with an internal O-ring to ensure a good seal.

Can I use Air-Lock with any type of drum?

Air-Lock® is specifically designed for steel drums with a standard 2" NPT thread. The drum must be in good condition and capable of holding slight pressure. It is not compatible with:

• Desiccant breathers

• Filter carts

• Non-steel or damaged drums

• Environments with extreme temperature fluctuations beyond 75°F (24°C)

Protect your investment;

every drop matters

Oil isn’t cheap, and neither are the consequences of contamination. With Air-Lock®, you get peace of mind knowing your product is stored in optimal condition—clean, dry, and ready to perform. It’s a simple addition with a massive return: lower maintenance costs, longer oil life, and reduced equipment downtime.